Is the lower the viscosity of a monomer, the stronger its dilution ability?

Release time:

2025-08-27

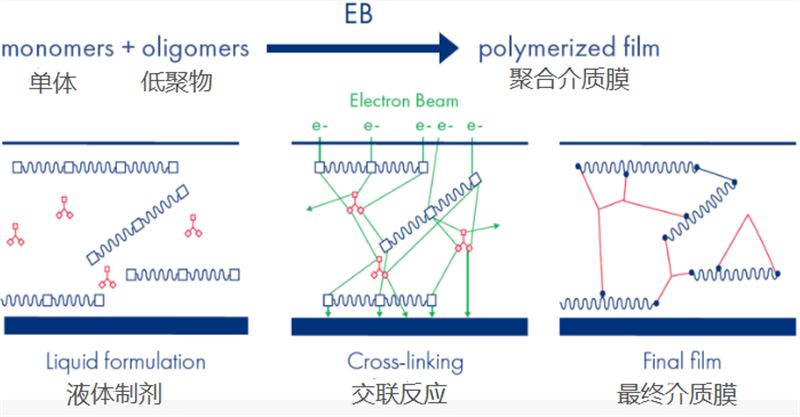

When working with resins and polymers, viscosity is a critical property that often dictates processing ease and the final material's characteristics. For formulators, particularly in UV-curable coatings, adhesives, and inks, the ability to reduce the overall viscosity of a system is paramount. This is where (methyl) acrylate monomers come into play as reactive diluents. A common assumption is that the lower the viscosity of a monomer, the stronger its dilution ability. But how accurate is this statement, and what other factors are at play? Let's dive in.

The Relationship Between Monomer Viscosity and Dilution Ability

In general, the statement holds true: monomers with lower intrinsic viscosity tend to be more effective at reducing the viscosity of a resin system. This is because lower viscosity monomers offer less resistance to flow and can more readily disentangle polymer chains, facilitating a reduction in the overall system's internal friction.

Imagine a thick syrup. If you add a very thin liquid to it, the syrup becomes easier to pour. The same principle applies to resin systems. Monomers act as solvents that participate in the final polymerization, effectively "thinning out" the resin while also becoming an integral part of the cured network.

However, "dilution ability" isn't solely about the monomer's individual viscosity. It's also influenced by:

Molecular Weight and Structure: Smaller molecules with less complex structures generally have lower viscosities and better dilution capabilities. Monomers with long, flexible chains or bulky side groups tend to have higher viscosities.

Compatibility with the Base Resin: The monomer must be miscible with the base resin to effectively dilute it. Poor compatibility can lead to phase separation, haziness, and ultimately, a compromised dilution effect.

Concentration Used: The higher the concentration of the reactive diluent, the more pronounced its effect on the system's viscosity.

Temperature: Viscosity is highly temperature-dependent. As temperature increases, the viscosity of most monomers and resin systems decreases.

Understanding Dilution Ability: Beyond Just Viscosity

While a monomer's neat viscosity is a good initial indicator, a more accurate measure of its dilution ability is often assessed by blending it with a standard resin and measuring the resulting viscosity reduction. This provides a more practical understanding of how it performs in a real-world formulation.

Let's consider a hypothetical chart illustrating the dilution effect of various monomers on a typical epoxy acrylate resin:

Monomer Type | Neat Viscosity (mPa·s @ 25°C) | Viscosity of 80/20 Blend with Resin (mPa·s @ 25°C) | Viscosity Reduction (%) |

Epoxy Acrylate | ~300,000 | N/A | N/A |

TMPTA | 100 | 50000 | 83% |

TPGDA | 13 | 25000 | 92% |

HDDA | 10 | 8000 | 97% |

IBOA | 8 | 6000 | 98% |

This chart is illustrative and values may vary depending on the specific resin and monomer grades.

From this table, we can observe that HDDA (Hexanediol Diacrylate) and IBOA (Isobornyl Acrylate), with their significantly lower neat viscosities, demonstrate a stronger dilution effect on the epoxy acrylate resin compared to higher viscosity alternatives like TMPTA (Trimethylolpropane Triacrylate).

Recommended UV/EB Curing Monomers with Strong Dilution Ability

For applications requiring significant viscosity reduction, formulators often turn to mono- or di-functional (methyl) acrylate monomers due to their inherently lower viscosities. Here are a few popular choices known for their excellent dilution capabilities:

Easmer HDDA,1,6-Hexanediol Diacrylate : A very common and highly effective reactive diluent. It has a very low viscosity, good solvency, and offers a balance of flexibility and hardness in the cured film. It's difunctional, contributing to a good crosslink density.

Easmer IBOA,Isobornyl Acrylate: Known for its extremely low viscosity and excellent adhesion properties. IBOA also imparts good surface hardness, chemical resistance, and weatherability to cured systems. Its cyclic structure provides rigidity.

Easmer TPGDA,Tripropylene Glycol Diacrylate: Offers a good balance of low viscosity and flexibility. It's a popular choice in many UV ink and coating formulations.

Easmer HEA,2-Hydroxyethyl Acrylate: Excellent in reducing viscosity of high molecular weight oligomers,It increases hydrophilicity and adhesion but may compromise water resistance

Conclusion

While the general rule of thumb holds – lower monomer viscosity often correlates with stronger dilution ability – it's crucial to consider the broader context of molecular structure, compatibility, and the desired final properties of the cured material. Formulators must balance the need for viscosity reduction with other performance requirements such as flexibility, hardness, chemical resistance, and adhesion. By carefully selecting the right reactive diluents, it's possible to achieve optimal processing viscosity without compromising the integrity and performance of the final product.

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-09-04

2025-09-04