A Primer on UV-Curable Pressure-Sensitive Adhesives

Release time:

2025-08-31

Introduction

Pressure-sensitive adhesives (PSAs) are ubiquitous—from tapes and labels to medical devices—bonding with a simple application of pressure without needing heat, water, or solvents. Among the various PSA technologies, UV-curable PSAs stand out for their rapid curing, environmental advantages, and high performance in demanding applications . Let’s explore what makes them tick.

Core Components & Formulation Essentials

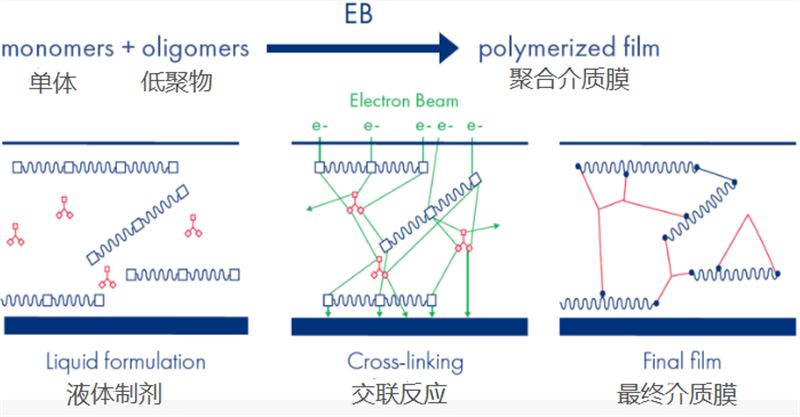

UV-curable liquid PSAs consist of four key components, whose combined properties—polymer rheology, molecular weight, functionality, and crosslink density—govern final performance :

Oligomers: Low-molecular-weight, often elastomeric (e.g., acrylated urethane) polymers that largely determine shear strength, tack, creep resistance, heat and chemical performance, and color retention .

Monomers: Serve to adjust viscosity and influence cure rates.

Photoinitiators: Absorb UV light to generate radicals or cations, initiating crosslinking.

Other additives: Tackifiers, copolymers, rheological modifiers, etc., further tailor adhesion traits.

Why Switch to UV-Curable PSAs? Advantages Across Technologies

UV-curable PSAs bring compelling benefits over conventional PSA types:

From Solvent-Based PSAs (e.g., solvent acrylic):

100% solids → no solvent evaporation: Eliminates yield loss and reduces equipment needs (no ovens or ventilation).

Fast cure speeds & thicker coatings in fewer passes.

Lower energy use (~85% less) and simpler plant layout.

Improved safety and environmental footprint.

From Hot-Melt PSAs:

Better UV, chemical, plasticizer, and high-temperature resistance—rubber-based hot melts often degrade under UV or heat.

Improved cold temperature tack and high-temperature shear due to chemical crosslinking.

Across All Technologies:

Compact processing lines: UV curing works inline without large dryers.

Long shelf life and logistics advantage: 100% solids systems are more robust during shipping/storage.

Versatility in coatings: Suited for specialty, label, tape, and graphics applications.

Henkel, a major adhesive manufacturer, highlights how UV-curable PSAs open new, profitable markets—from clear specialty labels to medium/high-performance tapes—while enhancing clarity, UV resistance, and thermal range.

Challenges & Innovations in UV PSA Technology

Light Penetration and Cure Depth

Formulating UV-curable adhesives is complex: ingredients like pigments, tackifiers, or photoinitiators can absorb or block UV light, reducing cure depth and uniformity.

Coating method (direct vs. transfer) also matters: direct-coated surfaces receive more UV and cure more fully, impacting shear vs. tack properties; transfer-coated surfaces may remain softer and stickier.

Dual-Cure (UV + Heat) Systems

To address curing in shadowed or thick areas, dual-curable formulations incorporate both UV-reactive and thermally reactive groups. Initial UV exposure starts crosslinking, followed by heat to complete cure—even in areas poorly exposed to light. This allows curing of coatings up to 1–2 mm thick and ensures balanced tack, peel, and shear performance.

Smart, Stimuli-Responsive PSAs

Researchers are developing “smart” PSAs whose properties—adhesion, conductivity, color, shape—can be reversibly switched using external stimuli like heat, light, or fields. While few are commercially available, they point to transformative future uses (e.g., switchable labels, detachable adhesives).

Emerging Chemistry: Anionic Photocuring

New work (2025) introduces photoanionic crosslinking systems—curing via anionic mechanisms using photobase generators. These systems cure rapidly in air and deliver high heat resistance (up to 220 °C shear-test failure), with peel strength around 1.3 N/cm, ideal for demanding temporary bonding (e.g., semiconductor fixative tapes).

Conclusion

UV-curable PSAs blend the convenience of pressure-sensitive adhesion with the speed, environmental benefits, and precision of photopolymerization. Thanks to tunable chemistry, they deliver enhanced adhesion performance, thermal and chemical resistance, and clean processing for high-value products—from electronics to specialty packaging.

Challenges like limited curing depth and UV penetration are actively being tackled through dual-cure strategies and novel polymer chemistry. As innovations like smart adhesives and anionic photoinitiator systems mature, UV-curable PSAs will likely expand into even more advanced, high-performance niches.

Quick Reference Table

Feature / Innovation | Benefit / Description |

Fast UV curing | Speeds production; immediate tack |

100% solids | No solvent evaporation; safer and cleaner |

Compact equipment | Eliminates need for ovens, vents |

Excellent thermal & chemical resistance | Enables demanding applications |

Dual-cure systems | Solves shadowed/thick-area curing |

Smart adhesives | Stimuli-responsive, high-value applications |

Anionic photochemistry | High-heat resistance and rapid cure in air |

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-09-04

2025-09-04