Managing Shrinkage in UV/EB Curing: Definition, Impacts, and Solutions

Release time:

2025-09-02

Shrinkage is a critical factor in many manufacturing processes, and nowhere is this more true than in the world of UV/EB curing materials. Understanding and controlling shrinkage can make the difference between a successful product and a costly failure. Let's explore the ins and outs of shrinkage rate, its impact, influencing factors, and solutions in UV/EB curing.

What Exactly is Shrinkage Rate?

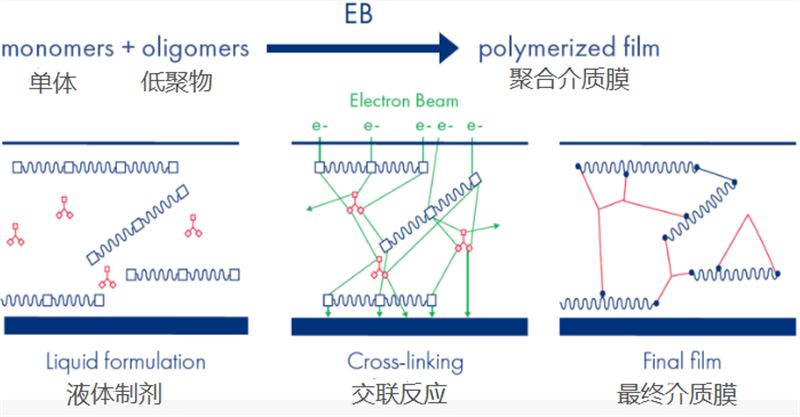

At its core, shrinkage rate refers to the reduction in volume or dimensions of a material as it transitions from a liquid or semi-liquid state to a solid state. This phenomenon is particularly prevalent in polymer chemistry, where monomers and oligomers link together to form long polymer chains. During this process, the individual molecules pack more closely together, leading to a decrease in overall volume.

In UV/EB curing, this transformation is initiated by ultraviolet (UV) light or electron beam (EB) radiation. These energy sources trigger a rapid polymerization reaction, cross-linking the liquid components into a solid film or object. The extent of this volume reduction is expressed as a percentage of the initial volume.

The Far-Reaching Impact of Shrinkage

The impact of shrinkage rate can be significant across various applications, affecting both performance and aesthetics.

Adhesives: High shrinkage in adhesives can lead to internal stress, reducing bond strength and potentially causing delamination, especially when bonding dissimilar materials.

Coatings: In coatings, excessive shrinkage can result in film stress, leading to defects like curling, warping, poor adhesion, and even cracking, particularly on flexible substrates or thick films.

3D Printing: For 3D printing applications, shrinkage is a major challenge. It can cause dimensional inaccuracies, part distortion (warping), and internal stresses that weaken the printed object.

Electronics: In encapsulants and protective coatings for electronics, shrinkage can induce stress on sensitive components, leading to electrical failures or reduced device longevity.

Dental Materials: Dental composites, for example, need low shrinkage to prevent marginal gaps between the filling and the tooth, which can lead to secondary caries and sensitivity.

Factors Influencing Shrinkage in UV/EB Curing Materials

Several key factors determine the shrinkage rate of UV/EB curing materials:

Monomer/Oligomer Type and Functionality:

Molecular Weight: Generally, lower molecular weight monomers and oligomers tend to have higher shrinkage rates because they undergo a greater relative change in packing density during polymerization.

Functionality: The number of reactive double bonds (functional groups) per molecule also plays a role. Materials with higher functionality (more reactive sites) often lead to more cross-linking and tighter packing, thus higher shrinkage. For example, di-functional acrylates will generally shrink less than tri-functional acrylates.

Conversion Rate: The extent to which the monomers and oligomers convert into polymer chains directly influences shrinkage. Higher conversion rates (meaning more unreacted double bonds have reacted) generally lead to greater shrinkage.

Cross-linking Density: Materials with a higher cross-linking density (more interconnected polymer chains) typically exhibit greater volumetric shrinkage due to the tighter network formation.

Filler Content: Incorporating inert fillers (like silica, talc, or fumed alumina) can significantly reduce shrinkage. Fillers don't polymerize and thus don't shrink, effectively diluting the shrinking resin matrix. The higher the filler loading, the lower the overall shrinkage.

Curing Conditions:

Irradiance/Dose: The intensity and total energy of UV/EB radiation can influence the speed and completeness of the cure, indirectly affecting conversion and thus shrinkage.

Temperature: Curing at higher temperatures can sometimes lead to slightly different polymer network structures and conversion rates, subtly impacting shrinkage.

Solutions for Mitigating UV/EB Curing Shrinkage

Fortunately, there are several effective strategies to minimize or control shrinkage in UV/EB curing materials:

Strategic Monomer/Oligomer Selection:

High-Molecular-Weight and Hyperbranched Oligomers:Prioritize oligomers with a high molecular weight and hyperbranched, 3D spherical structures. This choice helps minimize the relative volume change during polymerization.

Bulky Monomers:Use multi-ring or long-chain alkyl acrylate monomers, such as Easmer TMCHA, Easmer OPPEA, Easmer EOEOEA, Easmer LA, and Easmer SA. These monomers increase the free volume of the molecules, allowing them to adapt to stress without causing macroscopic shrinkage or warping.

Ring-Opening Monomers:For a cationic curing system, select ring-opening monomers like epoxies, such as EACA103 and EAEP521. These undergo ring-opening polymerization, which can result in very low shrinkage or even slight expansion during curing, effectively counteracting shrinkage.

Incorporation of Fillers: As mentioned earlier, adding inert inorganic or organic fillers is a highly effective method. Fillers reduce the overall volume of the shrinking resin matrix. The type, size, and loading of the filler need to be optimized for the specific application.

Controlled Curing Conditions: Optimizing the UV/EB dose and intensity can help achieve a balanced cure, minimizing over-cure (which can lead to higher shrinkage) while ensuring sufficient polymerization.

Multi-Stage Curing: For some applications, a multi-stage or step-curing process can be beneficial. This involves an initial partial cure, allowing the material to relax, followed by a final full cure. This can help distribute stress and reduce overall distortion.

Polymerizable Plasticizers: In some cases, specific reactive diluents or polymerizable plasticizers can be used to lower viscosity and stress while maintaining relatively low shrinkage.

Developing Novel Resins: Ongoing research in polymer chemistry is focused on developing new resin systems with inherently lower shrinkage characteristics, often involving hybrid systems that combine different polymerization mechanisms.

By carefully considering these factors and implementing appropriate solutions, manufacturers can effectively manage shrinkage rates in UV/EB curing materials, leading to improved product performance, enhanced durability, and greater overall quality across a vast array of industries.

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-09-04

2025-09-04