Helpful Assistant for UV/EB Curing: Reactive Amine Synergists

Release time:

2025-08-27

If you've ever marveled at the instant-dry hardness of a UV-cured coating on a floor or the crisp, scratch-resistant print on a beverage bottle, you've witnessed the magic of ultraviolet (UV) and electron beam (EB) curing technology. This rapid, eco-friendly process is a cornerstone of modern manufacturing. But behind every successful UV/EB formulation lies a silent workhorse, a crucial component that often doesn't get the spotlight: the Reactive Amine Synergist.

Today, we're diving deep into this essential additive. We'll explore what it does, how it works on a molecular level, where it's used, and how to choose the right one for your application.

1. The Role of the Reactive Amine Synergist

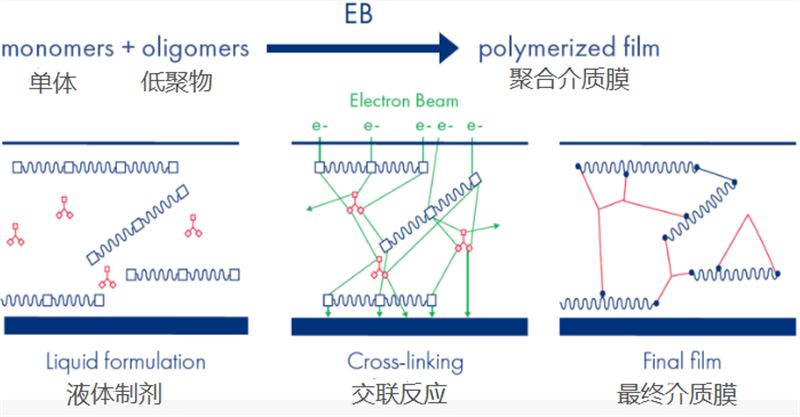

At its core, UV/EB curing is a process where liquid oligomers and monomers (the building blocks of the coating or ink) are transformed into a solid, cross-linked polymer network in a fraction of a second. This happens when photoinitiators absorb UV light and generate highly reactive free radicals, which kick-start the polymerization chain reaction.

However, there's a nemesis to this perfect reaction: oxygen.

Oxygen (O₂) is a diradical in its ground state and is highly effective at quenching free radicals. It reacts with them to form peroxy radicals, which are much less reactive and effectively halt the desired polymerization process. This phenomenon, known as oxygen inhibition, leads to a host of problems:

Tacky, uncured surfaces: The surface doesn't fully harden.

Reduced cure speed: Requires more energy (higher UV dose) to achieve a cure.

Poor physical properties: Lower gloss, reduced chemical and scratch resistance.

This is where the reactive amine synergist rides in to save the day. Its primary roles are to:

Scavenge Oxygen: React with oxygen dissolved in the formulation or present at the surface, reducing its concentration.

Regenerate Radicals: Its most important function is to donate a hydrogen atom to a stalled peroxy radical, generating a new, highly reactive radical that can re-enter the polymerization cycle.

The result? A faster, more complete surface cure, even in air, eliminating tackiness and unlocking the full potential of the formulation's properties.

2. The Reaction Mechanism

The mechanism is a beautiful example of chemical synergy. Let's break it down using molecular formulas. We'll represent a generic reactive amine synergist as R₂N-CH₂-R' (where R is often a alkyl group and R' contains a polymerizable group).

Step 1: The Problem – Oxygen Quenches a Radical

A growing polymer chain radical (P•) is quenched by oxygen, forming a sluggish peroxy radical.

P• + O₂ → P-O-O•

This peroxy radical is too stable to propagate the chain reaction efficiently.

Step 2: The Amine to the Rescue – Hydrogen Donation

The amine synergist (R₂N-CH₂-R') donates a hydrogen atom from its carbon alpha to the nitrogen. This is a key step.

P-O-O• + R₂N-CH₂-R' → P-O-O-H + R₂N-Ċ-R'

We now have a hydroperoxide (P-O-O-H) and, crucially, a new aminoalkyl radical (R₂N-Ċ-R').

Step 3: The Synergy – A New Reactive Radical is Born

This aminoalkyl radical is highly reactive and readily initiates new polymer chains by attacking double bonds in the resin system (acrylates are most common).

R₂N-Ċ-R' + CH₂=CH-C(O)-R'' (Acrylate Monomer) → R₂N-CH(R')-CH₂-Ċ-C(O)-R''

This new radical (CH₂-Ċ-C(O)-R'') continues the chain propagation reaction freely, effectively bypassing the roadblock created by oxygen.

The Net Effect: The amine doesn't get consumed without purpose; it acts as a catalytic intermediary, transforming a "dead" peroxy radical into a potent initiating radical, all while itself being incorporated into the polymer network thanks to its reactive group (R').

3. Applications of UV/EB Systems with Amine Synergists

Any UV/EB application cured in the presence of air (which is almost all of them) benefits tremendously from amine synergists. Key industries include:

Graphic Arts: Wood, plastic, and paper coatings, as well as inks for offset, screen, and flexographic printing, require tack-free surfaces for fast handling and stacking.

Packaging: Coatings for food packaging, beverage cans, and labels demand high gloss and resistance to scratching and chemicals.

Electronics: Conformal coatings and solder masks on circuit boards need complete surface cure for reliable performance.

Industrial Coatings: Floor coatings, automotive primers, and plastic parts require extreme durability and hardness that is only achievable with a full, inhibition-free cure.

4. Product Recommendations

Choosing the right amine synergist is crucial because it can affect yellowing, odor, and reactivity. Here are some product recommendations:

Tertiary Amine Synergists (e.g., Ethyl Dimethylaminobenzoate - EDB)

Hindered Amine Synergists (e.g., Alkylated Aminobenzoates)

Amine-Functionalized Acrylates (Reactive Amines): This is the most commonly used type of amine synergist on the market. They are not just additives but coreactants. They incorporate directly into the polymer network, significantly reducing odor and the potential for migration.

Amine-modified acrylate monomers, such as Easmer AS115, Easmer AS116, Easmer AS225, and Easmer AS335.

Tertiary amine-functionalized acrylate oligomers (under development).

Characteristics: These are not just additives but coreactants. They incorporate directly into the polymer network, significantly reducing odor and migration potential (a key factor for food packaging). They are often the preferred choice for high-performance, low-yellowing, and regulatory-compliant formulations.

Pro Tip: Always consult with your chemical supplier. The optimal choice depends on your specific resin system, photoinitiator package, and application requirements. Formulation is a science, and testing is key to success.

By understanding and effectively leveraging reactive amine synergists, formulators can defeat oxygen inhibition and unlock the full speed, efficiency, and performance that UV/EB technology promises.

Reactive Amine Synergist,AS115

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-09-04

2025-09-04