Monomers Matter: Selecting the Right Reactive Diluents for UV-Curing Pressure-Sensitive Adhesives

Release time:

2025-08-31

Introduction

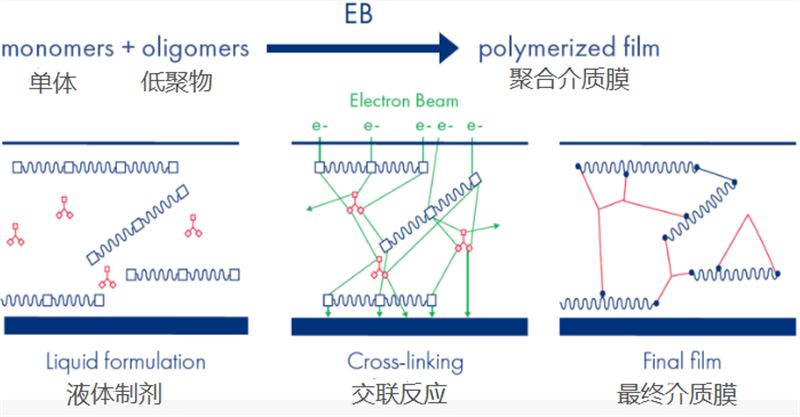

In UV-curable pressure-sensitive adhesives (UV-PSAs), monomers play a deceptively pivotal role. Far beyond reducing viscosity, they influence cure speed, adhesion, flexibility, and the mechanical profile of the finished adhesive. Let’s explore how monomer selection shapes performance, how to choose the right ones, and which monomers are formulator favorites.

1. How Monomers Influence PSA Performance

a) Viscosity & Processability

Most UV-oligomers are too viscous for coating—monomers lower viscosity into a workable 100–10,000 cP range, enabling smooth application.

b) Cure Kinetics & Crosslinking

Monofunctional monomers act as diluents: soft, flexible, and great for surface wetting and adhesion.

Multifunctional monomers (di-, tri-, poly-functional) serve as both diluents and crosslinkers, increasing cure speed, hardness, and chemical resistance.

c) Balancing Physical Properties

Higher monomer functionality increases crosslink density—leading to adhesives that are stiffer, more heat- and chemical-resistant—but sacrifice flexibility and elongation.

Formulators must strike a balance: rigid adhesives offer high shear strength; flexible ones deliver superior peel and impact resistance.

d) Conversion Rate vs Residual Unsaturation

Monomers with higher functionality cure faster—but often with lower overall conversion, leaving more unreacted double bonds in the film, impacting durability.

2. A Smart Strategy for Choosing Monomers

Here’s a streamlined decision map:

Define Performance Requirements

Need high peel and tack? Lean soft and mono-functional.

Need shear, heat or chemical resistance? Favor multifunctional.

Optimize Viscosity

Use lower-viscosity monofunctional monomers to thin heavy oligomers for better coating quality.

Blend Functionality

Create a synergy: monofunctionals for flexibility and crosslinkers for toughness.

Adjust Based on Substrate and Application

Hard, demanding surfaces (e.g., metals): include more crosslinkers.

Delicate substrates (e.g., skin films): minimize multifunctionals.

Tackle Surface Wetting

Monomers with lower surface tension improve wetting and adhesion to tricky substrates.

3. Recommended Monomers for UV/EB-Curable PSAs

Below is a practical selection of widely used monomers, grouped by function:

A. Monofunctional Acrylates (softness & tack)

n-Butyl Acrylate (BA): Flexible, low T_g, excellent tack.

2-Ethylhexyl Acrylate (2-EHA): Very soft, superior low-temperature adhesion.

Iso-Octyl Acrylate (IOA): High tack and adhesion to low-surface-energy lastics.

Isobornyl Acrylate (IBOA): Bulky monomer, improves cohesion, UV resistance, and chemical durability.

B. Multifunctional Acrylates (cohesion & durability)

Trimethylolpropane Triacrylate (TMPTA): Boosts crosslink density, shear resistance, and thermal stability.

Polyethylene Glycol Dimethacrylate (PEGDMA): Flexible difunctional monomer, enhances elasticity and adhesion on polar substrates.

Hexanediol Diacrylate (HDDA): Low-viscosity diluent, improves cure speed and cohesion.

Dipropylene Glycol Diacrylate (DPGDA): Balances viscosity reduction with moderate crosslinking.

C. Specialty Options (for fine-tuning)

Lauryl Acrylate (LA): Long alkyl chain, adds flexibility and low-T_g softness.

Hydroxyethyl Acrylate (HEA): Increases polarity and adhesion to glass/metal but reduces water resistance.

Cyclohexyl Methacrylate (CHMA): Adds rigidity and cohesion while maintaining good weathering resistance.

Conclusion

The performance of a UV-curable PSA depends heavily on the monomer mix. By combining soft monoacrylates for tack with multifunctional acrylates for cohesion, and leveraging specialty monomers like IBOA and PEGDMA for balance, formulators can design adhesives that meet diverse application needs—from medical tapes to industrial protective films.

In short: monomer selection is the key lever for tuning adhesion, cohesion, and processability in UV/EB-curable PSAs.

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-09-04

2025-09-04