Electron beam curing: Expected to become the driving force for industry development

Release time:

2025-09-04

Introduction: The Emergence of a Transformative Process

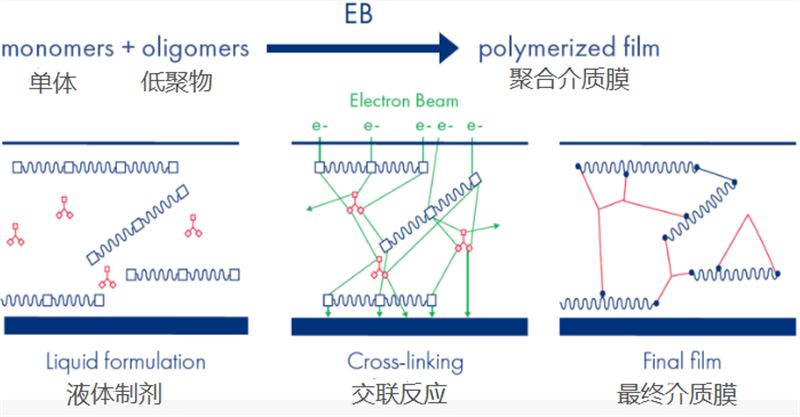

Electron Beam (EB) curing technology represents one of the most significant advances in modern materials processing. By using high-energy electrons to trigger rapid polymerization and crosslinking, EB curing bypasses the need for heat or chemical initiators, offering an efficient, solvent-free, and environmentally sustainable alternative to conventional curing methods.

Once limited to specialized applications, EB curing is increasingly recognized as more than just a technical solution—it may become a key engine driving industry development. Its dual role of delivering superior performance and supporting sustainability positions EB curing at the center of a future manufacturing ecosystem characterized by efficiency, safety, and environmental responsibility.

Part I: Tracing the Origins — From Scientific Discovery to Industrial Adoption

The origins of EB curing are rooted in the late 19th century, when physicists first observed “cathode rays,” later identified as streams of electrons. Early applications focused on managing the heat produced by electron impacts, but by the mid-20th century, researchers realized that electron beams could be harnessed for controlled thermal processing.

A decisive turning point came when high-energy electrons were found capable of initiating chemical reactions directly, at ambient temperatures. This breakthrough marked the beginning of EB curing technology. Initial industrial applications emerged in the 1970s, with the automotive and packaging industries adopting EB curing to address performance and safety requirements that conventional methods could not achieve.

Although early adoption was constrained by the high capital costs of EB equipment, the technology steadily advanced. With improvements in accelerator design and the introduction of more compact systems, EB curing has become increasingly accessible. This accessibility has strengthened its role not only as a manufacturing option but as a potential driver of industrial modernization, capable of reshaping production strategies across sectors.

Part II: The Science of Instant Curing — A Technical Perspective

At its core, EB curing uses accelerated electrons to directly ionize materials, initiating polymerization and crosslinking without the need for photoinitiators. Unlike ultraviolet (UV) curing, which requires photoinitiators to generate free radicals, EB curing provides a non-selective initiation mechanism, producing a wide variety of reactive species that result in densely crosslinked polymer networks.

Two independent parameters—dose (measured in kilograys, kGy) and energy (measured in kilovolts, kV)—enable precise control over the process. The dose influences the degree of crosslinking, while energy determines penetration depth. This dual control allows EB curing to accommodate both thin, heat-sensitive films and thick, multi-layer composites.

By enabling such precision, EB curing offers industries not just a technical tool but a competitive advantage that can reshape manufacturing efficiency. The table below highlights why EB curing is increasingly viewed as a technology that could power future industrial growth.

Table 1: A Comparative Analysis of Curing Technologies

Metric | Electron Beam (EB) Curing | Ultraviolet (UV) Curing | Thermal Curing |

Curing Mechanism | High-energy electrons directly ionize materials, initiating polymerization and crosslinking. | UV light activates a photoinitiator, which generates free radicals to initiate polymerization. | Heat is applied to evaporate solvents and initiate chemical reactions or melt solids. |

Speed | Instantaneous, seconds to milliseconds. | Fast, typically a few seconds. | Slow, can take minutes to hours or days. |

Energy Efficiency | Extremely high; up to 95% less energy than thermal and 80% less than UV. | High; more energy-efficient than thermal. | Low; requires significant energy to heat large volumes of air and substrates. |

VOC Emissions | None; 100% solids, solvent-free process. | Very low to none; relies on reactive monomers. | High; evaporates solvents and other volatile compounds. |

Heat Generation | Minimal to none; a non-thermal, “cold” process. | Significant, especially with mercury lamps. | High; requires heating the entire substrate to a specific temperature. |

Penetration Depth | Excellent; can cure thick, opaque, and highly pigmented materials. | Poor; limited to thin, clear coatings as it depends on optical clarity. | Depends on material properties and oven time. |

Initiator Required | No. | Yes, a photoinitiator. | No, but often requires catalysts. |

Ideal Applications | Heat-sensitive substrates, thick films, opaque coatings, food packaging, composites, sterilization. | Thin, clear coatings, transparent plastics, wood finishes, graphic arts. | General industrial coatings, powder coatings, epoxy resins. |

Part III: The Current Landscape — A Panorama of Applications and Innovations

Electron beam curing is a quiet but powerful revolution in manufacturing, with its influence extending across multiple industries. The technology's ability to deliver superior performance while enhancing sustainability has driven its adoption in applications where traditional methods fall short.

The Quiet Revolution in Packaging

The packaging industry represents one of the most significant and rapidly growing sectors for EB curing. The primary driver is its unique ability to ensure food safety. By eliminating the need for photoinitiators, EB curing prevents the risk of chemical migration from inks and coatings into food products. This is a critical advantage for major consumer brands like PepsiCo, which have publicly noted the superior consistency and safety factor of EB curing compared to UV technology.

Application Examples:

Flexible Packaging: EB is widely used to cure inks, overprint varnishes (OPVs), and laminating adhesives on flexible films. The instantaneous cure of laminating adhesives eliminates the typical 48–72 hour aging process required by conventional methods, significantly boosting manufacturing productivity.

Sustainable Materials: EB-curable OPVs are compatible with compostable and recyclable packaging, such as the Charter NEX GreenArrow pouch. Furthermore, EB-cured inks and coatings can break down during recycling, facilitating the effective recovery of paper and plastic otherwise difficult to process.

Heat-Sensitive Substrates: The non-thermal process makes EB ideal for materials such as shrink films and sleeves, where thermal curing would cause distortion.

High-Performance Coatings and Adhesives

EB curing is the technology of choice for high-performance applications that demand exceptional durability and quality.

Application Examples:

Automotive and Architectural Coatings: Initially adopted by Ford in the 1970s, EB curing is also applied in decorative laminates, producing scratch-resistant and color-stable surfaces.

Adhesives: In pressure-sensitive adhesives (PSAs), EB crosslinking enhances shear, heat, and chemical resistance. The instant cure also eliminates pot-life issues, providing consistent process control.

Coil Coatings: ArcelorMittal has demonstrated EB and UV hybrid curing in coil coating, replacing thermal ovens and reducing greenhouse gas emissions by up to 31%.

Aluminized Paper: EB coatings enhance the surface of paper, enabling solvent-free finishes such as matte or glossy effects prior to aluminum plating.

Advanced Materials and Beyond

The application of EB curing extends into advanced materials and biomedical fields.

Application Examples:

Composite Curing: EB curing supports rapid manufacturing of composites for aerospace and automotive industries, reducing thermal stresses and tooling costs.

Medical and Sterilization: EB is used for functional coatings on medical devices and as a sterilization method, destroying microbial DNA through chain scission.

Recent innovations in compact, low-voltage EB systems have further expanded accessibility, enabling wider industrial use.

Part IV: Charting the Future — Trends, Market Dynamics, and Emerging Horizons

The future outlook for electron beam curing is highly promising, driven by a powerful confluence of technological advancements and pressing market demands. The market for EB curable coatings is projected for steady growth. According to market analysis, the market was estimated at approximately USD 447 million in 2025, with projections to reach around USD 524 million by 2030, at a compound annual growth rate (CAGR) of 3.22%. A separate projection for the broader curable resin market estimates a value of USD 850 million by 2033 with a higher CAGR of 7%, indicating the technology's expanding applicability beyond just coatings.

The market’s geographical dynamics are notable, with the Asia-Pacific region standing as the largest and fastest-growing market. This growth is propelled by robust manufacturing bases, particularly in electronics, automotive, and packaging, with China leading the regional expansion.

The primary drivers propelling this growth are:

Environmental Regulations: Stricter global rules on VOCs and hazardous pollutants are pushing manufacturers toward solvent-free solutions.

Sustainable Production: Industry-wide initiatives to reduce energy consumption and emissions align directly with EB curing’s advantages.

High-Performance Demands: Industries require coatings with superior durability, hardness, and resistance, properties uniquely suited to EB curing.

Key technological innovations include:

Hybrid Systems: Combining EB’s penetration with UV’s surface precision for tailored effects.

AI and Automation: Real-time monitoring and predictive optimization ensure consistency and efficiency.

Advanced Materials: Hybrid acrylate/epoxy systems are being developed to expand into high-performance sectors such as aerospace.

Despite challenges such as the need for inert atmospheres in some applications, advances in compact EB equipment and new resin formulations are accelerating adoption.

As these developments converge, it becomes increasingly evident that EB curing is not only a specialized technical solution but may evolve into an engine of industry development. By driving efficiency, sustainability, and performance, EB curing can serve as a catalyst for industrial transformation in the coming decades.

Conclusion: Toward a Cleaner, Faster Future

Electron beam curing exemplifies how fundamental scientific insights can evolve into transformative industrial solutions. Its ability to initiate chemical reactions without heat or photoinitiators delivers unique benefits—instantaneous curing, high efficiency, zero VOC emissions, and superior material performance.

From food-safe packaging to aerospace composites, EB curing is reshaping industries while supporting global sustainability goals. As innovations in equipment and materials continue to lower barriers, EB curing has the potential to become the very engine driving industry development—powering a new era of cleaner, faster, and more sustainable production.

EB CURING

Previous Page

Next Page

Previous Page

Next Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-09-04

2025-09-04