Dicyclopentenyl Acrylate (DCPA): Alicyclic Structure for High-Performance UV/EB Curing

Release time:

2025-05-14

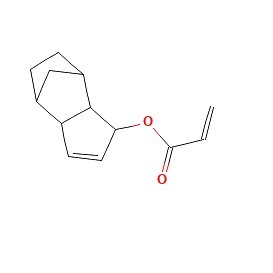

Dicyclopentenyl acrylate (DCPA, CAS 12542-30-2) is a monofunctional UV-curable monomer with a rigid bicyclic alicyclic backbone. Its chemical name (hexahydro-4,7-methano-1H-indenyl acrylate) reflects a fused bicyclic (“methanoindenyl”) ring attached to the acrylate group. This saturated dicyclic core severely restricts rotation and imparts high rigidity. As a result, polymers of DCPA exhibit very high glass-transition temperatures and hardness. For example, DCPA homopolymer has a Tg around 120 °C, far above that of many common acrylates. In practice, the rigid backbone yields coatings and resins with exceptional thermal and mechanical stability.

Performance Highlights

Glass Transition (Tg ≈ 120 °C): Polymers of DCPA are very rigid and heat-resistant. Its homopolymer Tg (~120 °C) exceeds that of common aliphatic acrylates, meaning DCPA-rich networks stay glassy and hard at elevated temperatures.

Hardness and Scratch Resistance: The rigid rings yield cured films with high hardness. Indeed, DCPA (and related dicyclopentanyl/methacrylates) are cited for producing coatings with excellent hardness and scratch resistance.

Low Curing Shrinkage: The bulky, inflexible monomer shrinks less on polymerization than flexible monomers. In practice, this helps maintain dimensional stability in bonded joints and precision optics.

Low Volatility: With a boiling point above 100 °C at near-atmospheric pressure and a low vapor pressure (0.9 Pa @20 °C, DCPA is much less volatile than small acrylates. This makes it a good choice where solvent-free or low-emission formulations are needed.

Hydrophobicity and Stability: The saturated alicyclic core is nonpolar. Cured DCPA networks are typically hydrophobic and chemically stable. For example, DCPA is noted for imparting hydrolytic stability and weather resistance to coatings.

Adhesive Performance: DCPA-containing formulations exhibit strong adhesion to many substrates. In UV-curable hardcoats, dicyclopentenyl (meth)acrylates are explicitly listed as monomers that give excellent adhesion and hardness.

Specifications of Easmer DCPA

Appearance | Clear liquid |

Color /APHA | 50 Max |

Viscosity/cps@25℃ | 8-18 |

Acid Value/ mgKOH/g | 0.5 Max |

Moisture /wt.% | 0.1 Max |

Inhibitor MEHQ /ppm | 500 Max |

Application Fields

Because of its above features, DCPA sees use as a specialty monomer/reactive diluent in various high-performance UV/EB-curable formulations:

UV/EB Curing Systems: DCPA is widely used in 100%-solids (radiation-curable) inks, coatings, and sealants. Its low volatility and high reactivity make it an effective reactive diluent to adjust viscosity without sacrificing cured Tg. It supports fast UV cure with high monomer conversion. For example, vendors note DCPA as a key diluent in UV-curable coatings and adhesives.

High-Performance Coatings: In industrial and protective coatings, DCPA imparts hardness, abrasion resistance, and heat stability. Coatings with DCPA have improved weathering and chemical resistance. It is also used in specialized UV-curable clearcoats and hardcoats for electronics and optics.

Adhesives and Sealants: DCPA is used in UV-curable adhesives (including pressure-sensitive and structural adhesives) where high bond strength and low shrink are critical. Its rigid structure gives cured adhesives high shear and creep resistance. Companies report DCPA in adhesive formulations for electronics, optical fibers, and composite bonding.

Optical Materials: The combination of low shrinkage, good adhesion, and high rigidity makes DCPA suitable for optical bonding and coatings. UV-curable optical adhesives often require minimal shrinkage and dimensional stability; DCPA-based systems help meet these needs. (For example, low-shrink optical adhesives designed for precision optics often contain alicyclic acrylates like DCPA.)

3D Printing Resins: The low shrinkage and rapid curing properties of DCPA enhance printing accuracy and efficiency.

In summary, DCPA’s rigid alicyclic backbone translates directly into performance: high thermal stability and hardness, low shrinkage, and low volatility. These qualities suit it for demanding UV/EB-cured products (coatings, adhesives, films, etc.) where standard acrylates fall short. Its broad utility in the formulation of high-performance radiation-curable resins has been noted in multiple technical sources, making DCPA a valuable component in advanced acrylate systems.

For more information or technical data, feel free to contact us today!

DCPA,CAS 12542-30-2,High-Performance UV/EB Curing

Previous Page

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-05-14

2025-05-14