A Complete Guide to Photopolymerization 3D Printing Technologies and Applications(Part 4)

Release time:

2025-05-08

Chapter 5: Applications of Photopolymerization-Based 3D Printing

Photopolymerization-based 3D printing has become a versatile technology with applications across numerous industries. Its unique ability to produce high-resolution, complex structures has led to its adoption in fields ranging from healthcare and optics to microfluidics and advanced manufacturing. This chapter explores the most prominent application areas, highlighting how photopolymerization has transformed each sector.

5.1 Optical Applications

Custom Lenses and Optics:

Photopolymerization enables the production of complex optical components such as lenses, prisms, and light guides.

High transparency and customizable refractive index are critical for these applications.

Waveguides and Photonic Devices:

Direct 3D printing of waveguides for integrated photonic circuits.

Precise control over refractive index and geometry for optimal light transmission.

Holographic Elements:

Photopolymerization can create custom diffraction gratings and holographic devices.

Used in augmented reality (AR) displays and optical sensors.

Application Examples:

Custom eyeglass lenses for individuals.

Optical filters for cameras and medical imaging devices.

Light guides for automotive headlamps.

5.2 Biomedical and Dental Applications

Medical Models and Surgical Guides:

Patient-specific anatomical models for surgical planning.

Biocompatible resins ensure safety for medical use.

Tissue Engineering and Bioprinting:

Photopolymerization is used to produce scaffolds for tissue growth.

Biocompatible and biodegradable hydrogels allow cell proliferation.

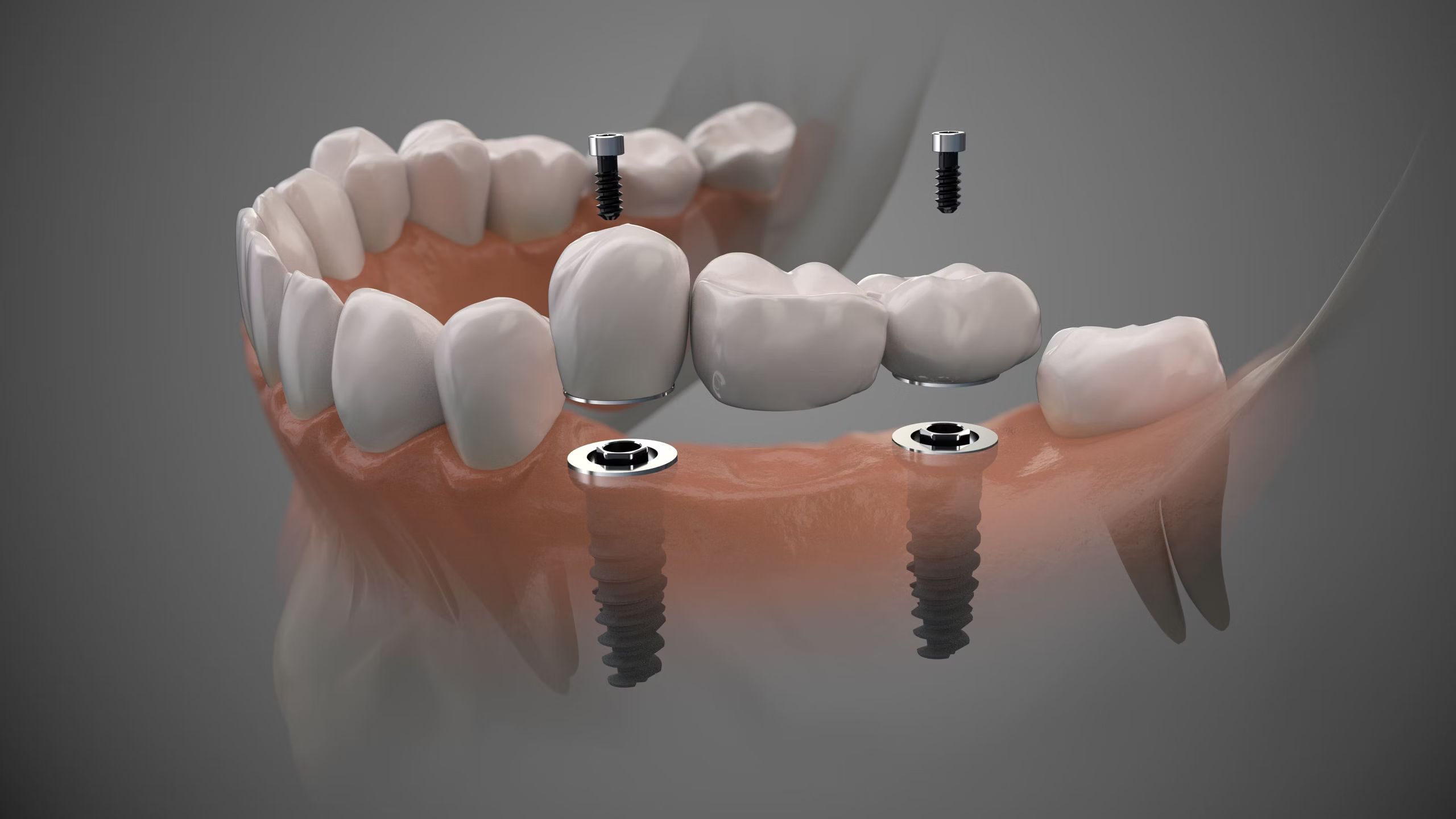

Dental Products:

Custom dental aligners (clear braces), crowns, and surgical guides.

High-precision SLA and DLP printers dominate this field.

Drug Delivery Systems:

Micro-structured drug delivery devices for controlled release.

Photopolymerization enables the fabrication of complex microfluidic channels.

Application Examples:

Custom prosthetics and orthotics.

Patient-specific implants.

Advanced bioprinting of tissue scaffolds.

5.3 Microfluidics and Lab-on-a-Chip Devices

Microfluidic Chips:

Photopolymerization is ideal for fabricating microfluidic devices due to its high resolution.

Used for biological assays, chemical analysis, and point-of-care diagnostics.

Integrated Sensors:

Sensors can be embedded directly within microfluidic channels.

Enables real-time monitoring of chemical reactions or biological processes.

Lab-on-a-Chip Systems:

Miniaturized laboratories that perform multiple tests on a single chip.

Used in medical diagnostics, environmental monitoring, and drug testing.

Application Examples:

Blood analysis devices.

Environmental toxin detectors.

Portable diagnostic kits for infectious diseases.

5.4 Advanced Manufacturing

Automotive Industry:

High-performance parts such as light guides, engine components, and seals.

Photopolymerization offers high precision and design freedom.

Aerospace Industry:

Lightweight yet strong components, such as brackets, housings, and lenses.

Custom optical sensors for aircraft systems.

Consumer Electronics:

Custom enclosures, buttons, and wearable device components.

Transparent displays and lenses for AR/VR devices.

Application Examples:

Custom dashboard elements in vehicles.

Lightweight aerospace brackets with complex internal structures.

Transparent components for smart glasses.

5.5 Artistic and Cultural Applications

Custom Jewelry and Fashion:

Complex, intricate jewelry designs that cannot be produced using traditional methods.

Resin casting patterns for precious metals.

Cultural Heritage Preservation:

Reproducing fragile or damaged artifacts using high-resolution 3D printing.

Creating detailed replicas for museum displays.

Creative Sculptures and Design:

Artists use photopolymerization to create sculptures with complex geometries.

Custom lighting fixtures with optical effects.

Application Examples:

Custom rings and pendants.

Artistic sculptures with internal light effects.

Replicas of ancient artifacts for educational purposes.

5.6 Electronics and Wearable Devices

Printed Circuit Boards (PCBs):

Conductive photopolymers allow the direct printing of flexible circuits.

Used in wearable electronics and smart devices.

Microelectromechanical Systems (MEMS):

Precision 3D printing of MEMS for sensors and actuators.

Used in automotive, medical, and consumer electronics.

Smart Devices:

Flexible sensors, touchpads, and light guides for smartwatches.

Custom-fit earphones with integrated electronics.

Application Examples:

Wearable health monitors.

Smart glasses with integrated optical systems.

Customized electronic casings and housings.

5.7 Emerging Applications

Environmental Monitoring:

Customized sensors for detecting pollutants in water or air.

Microfluidic devices for rapid environmental testing.

Food and Beverage Industry:

Custom molds for food products (chocolates, gummies).

Printed food decorations with complex shapes.

Educational Tools:

Custom anatomical models for medical training.

Interactive teaching aids for chemistry and physics.

Smart Packaging:

Interactive labels with embedded optical elements.

Anti-counterfeiting features for high-value products.

5.8 Application Case Studies

Case Study 1: Custom Dental Aligners

A dental clinic uses SLA 3D printing to create patient-specific clear aligners.

Fast production and high precision reduce patient waiting time.

Case Study 2: Microfluidic Diagnostic Device

A medical startup produces lab-on-a-chip devices for rapid blood testing.

Photopolymerization allows high-resolution channels for precise fluid control.

Case Study 3: Aerospace Light Guides

An aerospace company 3D prints custom light guides for aircraft interiors.

Photopolymerization enables lightweight, high-performance optics.

5.9 Summary of Applications

Industry | Applications | Benefits of Photopolymerization |

Optical | Lenses, waveguides, holograms | High resolution, customizable optical properties |

Biomedical | Surgical guides, dental devices, tissue scaffolds | Biocompatibility, precision, complex geometries |

Microfluidics | Lab-on-a-chip, diagnostic devices | High-resolution channels, rapid prototyping |

Manufacturing | Automotive parts, aerospace components | Lightweight, strong, complex structures |

Cultural Arts | Jewelry, artifact preservation, sculptures | Intricate designs, transparency, high detail |

Electronics | Wearable devices, flexible circuits, MEMS | Precision, multi-material capabilities |

Environmental | Pollution sensors, smart packaging | Customizable designs, transparency for sensing |

This chapter has demonstrated how photopolymerization-based 3D printing has transformed various industries by enabling the creation of precise, complex, and high-performance components. In the next chapter, we will discuss the challenges and future trends facing this technology.

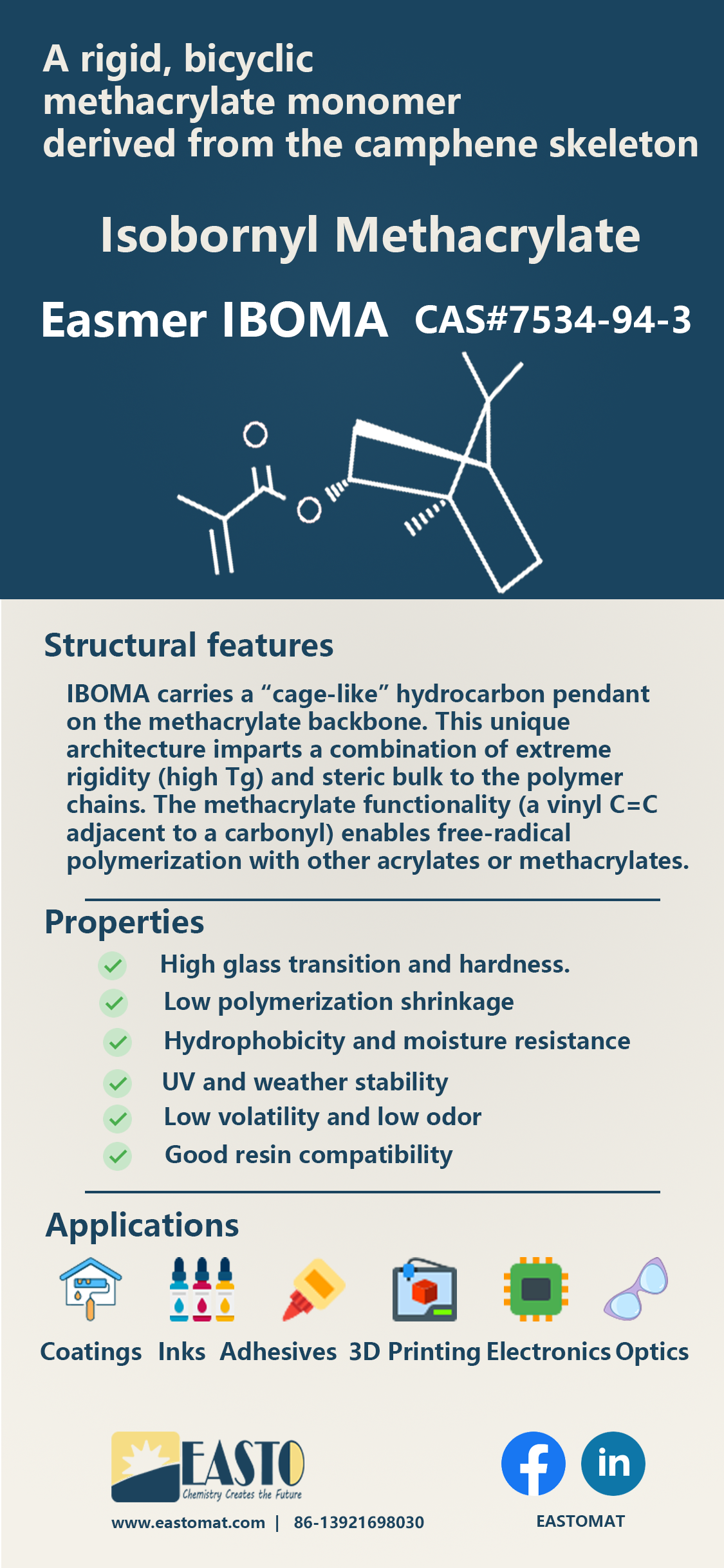

Photopolymerization 3D Printing,additive manufacturing,3D Printing Materials,DLP,SLA

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-05-14

2025-05-14