A Complete Guide to Photopolymerization 3D Printing Technologies and Applications(Part 5)

Release time:

2025-05-08

Chapter 6: Challenges and Future Trends in Photopolymerization-Based 3D Printing

Photopolymerization-based 3D printing is a powerful and versatile technology, but it is not without its challenges. This chapter explores the key technical, material, and sustainability challenges facing the industry. It also highlights the latest innovations and future trends that are expected to shape the evolution of this technology.

6.1 Technical Challenges

1. Limited Material Properties:

While photopolymer resins offer excellent resolution, they often lack the mechanical strength, heat resistance, or flexibility of thermoplastic polymers.

Common resins can be brittle, limiting their use in load-bearing applications.

2. Layer Adhesion and Anisotropy:

Layer-by-layer printing can result in weak interlayer bonding.

Printed objects may have different mechanical properties along different axes.

3. Light Scattering and Overexposure:

Highly transparent resins can cause light scattering, reducing print accuracy.

Overexposure can lead to unwanted curing of adjacent regions (light bleed).

4. Resolution Limitations:

The resolution of photopolymerization is limited by the size of the light beam (SLA) or pixel size (DLP).

Ultra-high-resolution prints require specialized equipment and longer print times.

5. Post-Processing Requirements:

Printed parts must often be cleaned, cured, and polished.

Post-processing can be time-consuming and may affect part quality.

6.2 Material Challenges

1. Resin Toxicity:

Many photopolymer resins contain hazardous chemicals that require careful handling.

Biocompatible and eco-friendly resins are still limited in variety and performance.

2. Limited Color Options:

Most resins are available in clear or a small range of colors.

Multi-color or gradient printing is challenging without specialized equipment.

3. Storage Stability:

Photopolymer resins are sensitive to light and temperature.

Extended exposure to light can cause premature polymerization or degradation.

4. Resin Waste Management:

Unused or partially cured resin must be properly disposed of.

Environmental concerns are growing around resin waste and recycling.

6.3 Sustainability Challenges

1. Resin Recycling:

Recycling photopolymer resin is difficult due to its chemical structure.

Most printed parts cannot be easily melted and reformed.

2. Energy Consumption:

High-resolution printing requires significant energy for light sources.

Post-processing (UV curing, cleaning) adds to energy consumption.

3. Limited Biodegradable Resins:

Although biocompatible resins exist, fully biodegradable options are rare.

Development of plant-based and biodegradable resins is still in early stages.

4. Environmental Impact of Waste:

Disposal of resin waste can lead to chemical pollution if not properly managed.

Strict regulations are emerging for resin disposal and recycling.

6.4 Future Trends and Innovations

1. Advanced Resin Development:

New formulations with enhanced mechanical, thermal, and optical properties.

Smart resins that change properties in response to external stimuli (light, temperature).

2. Multi-Material Printing:

Printers capable of using multiple resins in a single print.

Enables gradient structures and parts with variable mechanical properties.

3. High-Resolution Microfabrication:

Advances in light source technology (multi-photon lithography) for nanometer-scale printing.

Applications in micro-optics, MEMS, and biological scaffolds.

4. Eco-Friendly Resins and Recycling:

Development of plant-based, biodegradable, and recyclable photopolymers.

Innovations in resin recovery and reuse.

5. Improved Light Sources:

Variable-wavelength light sources for multi-material printing.

More efficient LED systems with longer lifespans.

6. AI-Driven Optimization:

Machine learning algorithms for optimizing print parameters (exposure, layer height).

Predictive models for material properties and print quality.

7. Integration with Digital Manufacturing:

Use of photopolymerization 3D printing for tooling, molds, and production parts.

Hybrid manufacturing systems combining 3D printing with CNC machining.

6.5 Emerging Applications Driving Innovation

Biomedical Innovations:

Bioprinting of complex tissue structures using cell-laden hydrogels.

Custom implants with enhanced biocompatibility.

Advanced Optics:

Gradient index (GRIN) lenses for AR/VR devices.

Complex free-form optics for cameras and sensors.

Sustainable Manufacturing:

Resin systems with low-carbon production methods.

Circular economy models for resin recycling.

Smart and Adaptive Materials:

Resins that change stiffness, color, or shape under specific conditions.

Applications in soft robotics and adaptive prosthetics.

6.6 Looking Ahead: The Future of Photopolymerization-Based 3D Printing

Photopolymerization-based 3D printing has grown far beyond its origins in prototyping, becoming a critical tool for production, healthcare, and advanced research. The future of this technology will be defined by several key trends:

Customization at Scale: Advanced multi-material and multi-color systems will enable personalized products in fields such as healthcare and consumer electronics.

Sustainability Focus: Eco-friendly resins, energy-efficient printers, and closed-loop recycling systems will become industry standards.

Precision and Complexity: Enhanced resolution through multi-photon lithography and advanced light control will drive applications in microelectronics, optics, and bioengineering.

Digital Integration: AI-powered design optimization, real-time process monitoring, and seamless integration with digital manufacturing systems will enhance productivity.

New Markets: Emerging applications in aerospace, environmental monitoring, and consumer electronics will continue to expand the adoption of photopolymerization.

This chapter has explored the challenges facing photopolymerization-based 3D printing and the exciting innovations on the horizon. In the final chapter, we will provide a comprehensive industry analysis, including market trends, key players, and future opportunities.

Chapter 7: Industry Analysis and Market Trends of Photopolymerization-Based 3D Printing

This final chapter provides an in-depth analysis of the photopolymerization-based 3D printing industry, covering market dynamics, major players, growth trends, and future opportunities. Understanding the market landscape is crucial for businesses looking to invest in this technology or compete in the space.

7.1 Market Overview

Global Market Size:

The photopolymerization 3D printing market has experienced significant growth over the past decade, driven by advancements in resin formulations, printer technology, and expanding application areas.

Current estimates value the global photopolymerization 3D printing market at over USD 2 billion, with a projected CAGR of 15–20% over the next five years.

Key Market Segments:

By Technology:

SLA (Stereolithography)

DLP (Digital Light Processing)

CLIP (Continuous Liquid Interface Production)

TPP (Two-Photon Polymerization)

CAL (Computed Axial Lithography)

By Application:

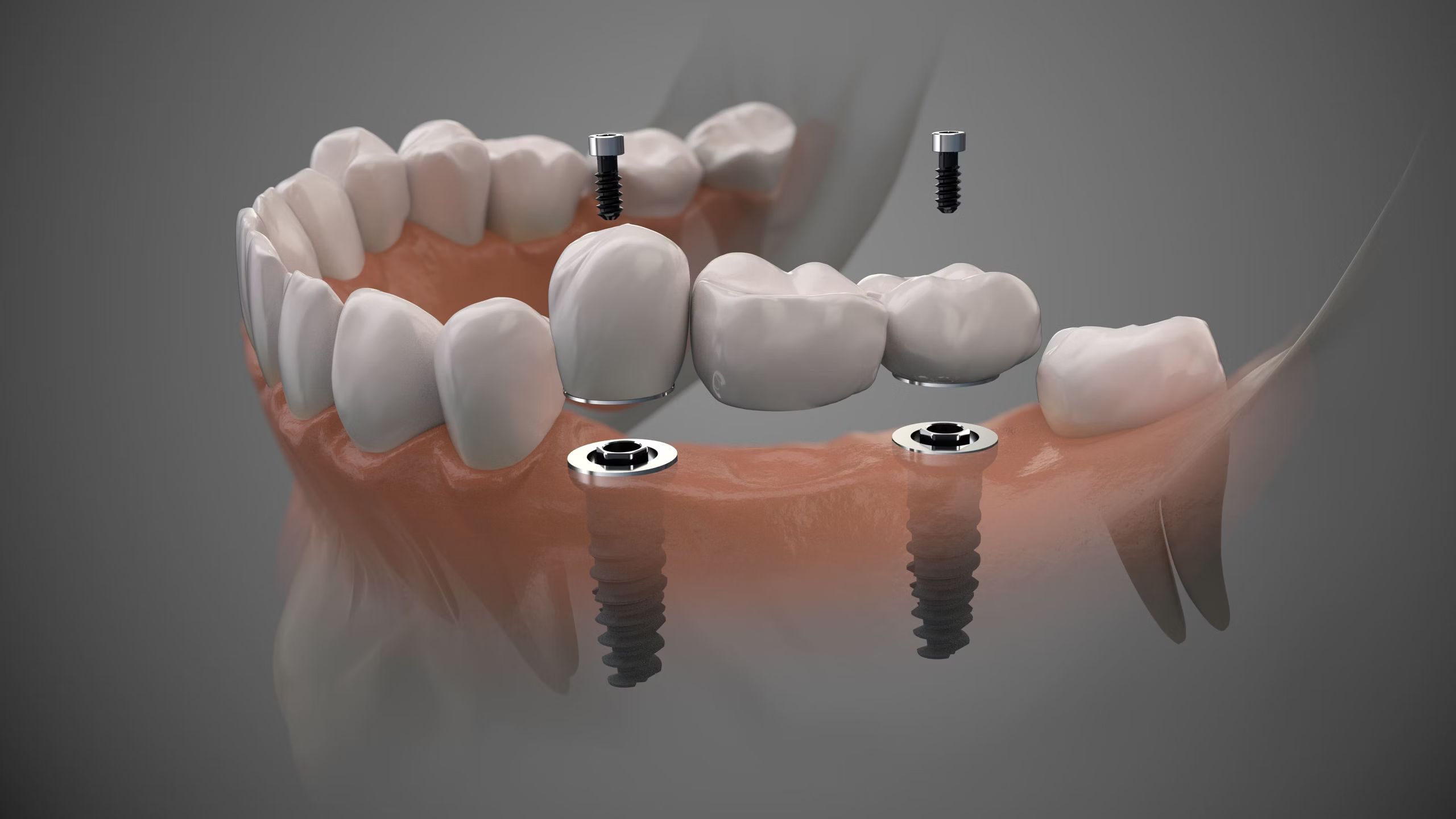

Healthcare (medical models, dental, bioprinting)

Consumer Goods (eyewear, jewelry, custom products)

Aerospace and Automotive (optics, lightweight parts)

Electronics (PCBs, MEMS, smart devices)

Industrial Prototyping and Manufacturing

By Material:

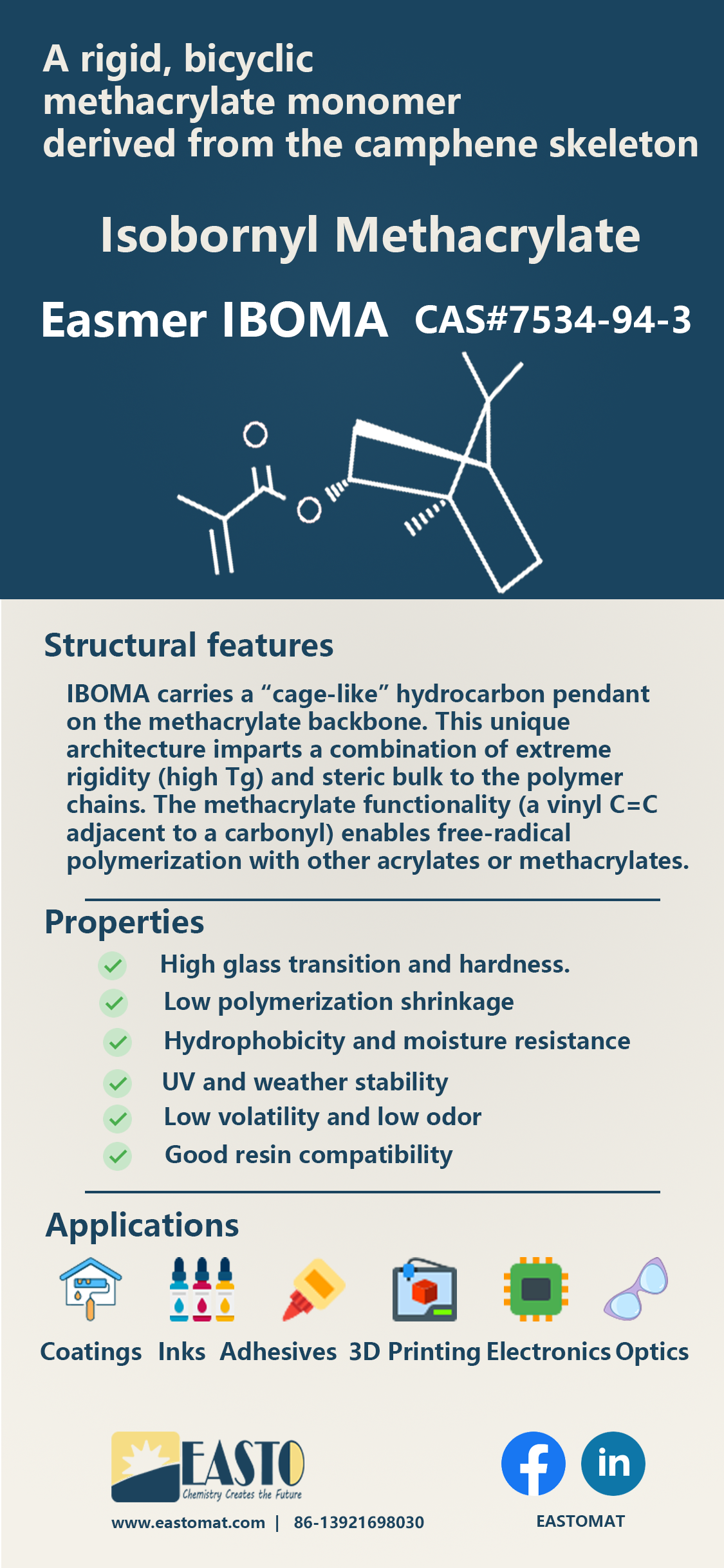

Standard Photopolymers (acrylates, epoxies)

Biocompatible Resins

High-Performance Resins (ceramic-filled, conductive)

Sustainable Resins (biodegradable, plant-based)

7.2 Market Drivers and Restraints

Key Market Drivers:

Advancements in Resin Technology: New formulations with enhanced mechanical, optical, and thermal properties.

Growing Demand in Healthcare: Custom dental devices, surgical guides, and biocompatible implants.

Miniaturization and Precision: Increased use in microfluidics, MEMS, and optics.

Customization Potential: Photopolymerization is ideal for producing custom-fit products.

Market Restraints:

High Material Costs: Specialized resins remain expensive.

Limited Material Properties: Many photopolymer resins are brittle or lack heat resistance.

Regulatory Compliance: Strict regulations for biocompatible and medical resins.

Environmental Concerns: Disposal of resin waste and limited recyclability.

7.3 Competitive Landscape

Leading Companies in Photopolymerization 3D Printing:

3D Systems: A pioneer in SLA technology with a wide range of photopolymer printers and resins.

Formlabs: Known for its affordable, high-resolution SLA and LFS printers.

Stratasys: Provides industrial-grade DLP systems for healthcare and manufacturing.

Carbon (Carbon 3D): Innovator of CLIP technology, focusing on dental, automotive, and consumer products.

EnvisionTEC (now part of Desktop Metal): Specializes in DLP technology for dental and jewelry.

Asiga: High-precision DLP printers for dental and medical applications.

XYZprinting: Offers consumer and professional DLP 3D printers.

Emerging Players:

BMF (Boston Micro Fabrication): Specializes in high-resolution TPP printing.

Ackuretta: Focuses on dental and medical 3D printing with biocompatible resins.

Anycubic and Elegoo: Popular for affordable consumer SLA/DLP printers.

Strategic Partnerships and Mergers:

Carbon and Adidas partnership for 3D-printed midsoles.

Desktop Metal’s acquisition of EnvisionTEC to expand its photopolymer capabilities.

7.4 Regional Market Insights

North America:

Largest market for photopolymerization 3D printing, driven by strong demand in healthcare and aerospace.

Major players like 3D Systems and Carbon are headquartered in the US.

Europe:

Significant adoption in dental and medical sectors.

Strong focus on sustainable materials and recycling.

Asia-Pacific:

Fastest-growing market due to increasing adoption in consumer goods and electronics.

China, Japan, and South Korea are key regional players.

Latin America and Middle East:

Emerging markets with increasing adoption in healthcare and automotive.

7.5 Recent Innovations and Disruptive Technologies

Multi-Material Printing:

Printers capable of using multiple resins in a single print, allowing gradient structures and complex assemblies.

Micro/Nano-Scale Printing:

Two-photon polymerization (TPP) enables nanometer-scale structures, driving applications in micro-optics and MEMS.

Sustainable Resins:

Development of biodegradable and plant-based resins aligns with global sustainability goals.

High-Performance Resins:

New resin formulations with enhanced heat resistance, strength, and chemical durability for industrial applications.

Smart Photopolymers:

Resins that change color, shape, or mechanical properties under external stimuli (light, heat).

7.6 Key Market Trends

Healthcare Dominance:

Dental applications remain the largest segment, followed by surgical guides and prosthetics.

Biocompatible and antimicrobial resins are gaining traction.

Expansion in Consumer Electronics:

Transparent resins for AR/VR optics, flexible photopolymers for wearable devices.

Growth in printed micro-optics for compact camera modules.

Customization at Scale:

Mass customization in eyewear, hearing aids, and jewelry.

Integration of photopolymerization with cloud-based design and production.

Sustainability Initiatives:

Development of eco-friendly resins and closed-loop recycling systems.

Circular economy models for resin recovery and reuse.

7.7 Future Opportunities

Biofabrication and Tissue Engineering:

Use of biocompatible and bioactive photopolymers for tissue scaffolds and organ models.

High-Performance Manufacturing:

Advanced resins for automotive and aerospace applications, replacing metal parts.

Smart Devices and Optics:

Continued development of smart lenses, light guides, and optical sensors.

Educational and Research Applications:

Photopolymerization for producing low-cost, high-precision teaching models.

Automated Production Systems:

Integration of AI-driven design and automated post-processing for scalable production.

7.8 Conclusion

The photopolymerization-based 3D printing industry is at an exciting point of transformation. With rapid advances in resin chemistry, light source technology, and multi-material printing, the technology is expanding into new markets and applications. Companies that innovate in sustainable resins, high-performance materials, and automated production are well-positioned for success.

Photopolymerization 3D Printing,additive manufacturing,3D Printing Materials,DLP,SLA

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-05-14

2025-05-14