Formulation and Process Strategies for Improving Adhesion

Release time:

2025-07-28

In the previous article, we reviewed the basic mechanisms, influencing factors, and failure modes of coating adhesion. This article will further discuss how to actively improve the adhesion performance of coating systems. From material formulation, substrate treatment to application processes, this article will systematically analyze improvement strategies and technical routes.

1. Optimizing Adhesion from a Formulation Design Perspective

1. Selecting Resins and Monomers with Polar Functional Groups

One of the fundamental ways to improve adhesion is to introduce polar or active functional groups, enabling the coating film to possess stronger chemical bonding or hydrogen bonding capabilities:

Functional Group Type | Functional Description | Representative Components |

Hydroxyl (–OH) | Improves hydrophilicity, facilitates reaction with metal/glass substrates | HEA, HEMA, polyurethane resins |

Carboxyl (–COOH) | Can chelate metal ions to form salt bridges | Acrylic resins, epoxy acrylates |

Amine (–NH2) | Provides hydrogen bonding and complexation | Polyamides, polyurea dispersions |

Ester/Ether | Provides good wettability | Polyester resins, PEG-type additives |

Especially in UV coatings or water-based systems, the introduction of functional groups balances reactivity, wettability, and flexibility.

2. Adding Adhesion Promoters

Adhesion promoters are a class of small molecule or polymer additives commonly used to improve interfacial bonding on non-polar or difficult-to-adhere substrates:

Silane Coupling Agents: Such as γ-glycidoxypropyltrimethoxysilane (GPS), suitable for inorganic substrates like glass and metals.

Phosphate Ester Additives: Can chelate metal ions, improving adhesion of coatings to aluminum and galvanized steel.

Polyamide Waxes, Fluorocarbon Wetting Agents: Possess both spreading and penetrating functions, suitable for complex surfaces.

Functionalized Polyurethane Dispersions: Perform particularly well in water-based systems, providing flexibility and polarity.

The addition amount should be controlled between 0.5–3.0%; excessive amounts may cause reaction interference or migration precipitation.

3. Rational Design of Crosslinking Density and Flexibility

Adhesion is often positively correlated with coating film flexibility. It is recommended to alleviate interfacial stress by adjusting crosslinking density or introducing flexible chain segments (such as aliphatic monomers, polyether structures).

In UV systems, introduce PETA, TMPTA, and flexible monomers (such as IBOA, EOEOEA) for synergistic use.

In two-component polyurethane systems, the prepolymer to hardener ratio can affect the balance between hardness and adhesion.

For metal substrates, the crosslinking density should not be too high to avoid brittleness.

2. Substrate Treatment Technologies: Creating a Good "Adhesion Interface"

1. Physical Treatment Methods

Method | Principle | Application Notes |

Sanding | Provides roughness, enhances mechanical interlocking | Wood, metal, plastic |

Sandblasting | Removes rust and contamination layers | Heavy-duty anti-corrosion, metal pre-treatment |

Flame Treatment | Surface activation, increases polar groups | PE/PP and other low-polarity plastics |

Corona/Plasma Treatment | Enhances surface energy | Electronic product coating, PET film |

Note the tolerance of different materials to treatment methods to avoid excessive damage to the substrate.

2. Chemical Treatment Methods

Acid/Alkaline Washing: Used for removing oxide layers on metal surfaces.

Phosphating/Chromating: Forms a dense inert film on metal surfaces, improving corrosion resistance and adhesion.

Equivalent Pre-treatment Agents: Such as zirconium-based and silane-based environmentally friendly alternatives.

Primer Application: Designed to match the system, used for difficult-to-adhere substrates.

In modern coating, phosphorus-free/chromium-free green treatment technologies have gradually replaced traditional phosphating processes.

3. Control of Application and Curing Conditions

Even if materials and surface treatment are well-designed, adhesion may still be difficult to guarantee if application and curing conditions are not met.

1. Controlling Environmental Parameters During Application

Temperature: It is recommended to keep the substrate and ambient temperature between 20−30∘C.

Humidity: Under high humidity conditions, the coating film is prone to absorbing water, reducing adhesion.

Cleanliness: Before application, thoroughly remove oil and dust; isopropyl alcohol and alcohol ester cleaning agents are recommended.

2. Optimizing Coating Methods and Drying Conditions

Multiple thin coats are better than one thick coat to reduce stress concentration.

UV/EB systems should ensure that irradiation intensity, energy density, and wavelength are matched.

Thermosetting systems need to control the heating curve to prevent premature film sealing.

3. Intercoat Adhesion Design for Multi-layer Systems

Use intermediate and base coat materials to connect various coating layers.

Appropriately sand the surface of old coating films to improve adhesion surface roughness.

Intercoat curing time and crosslinking degree need to be controlled within the "window period".

4. Practical Case Studies for Adhesion Improvement

Case 1: Insufficient UV Paint Adhesion on Aluminum Plate

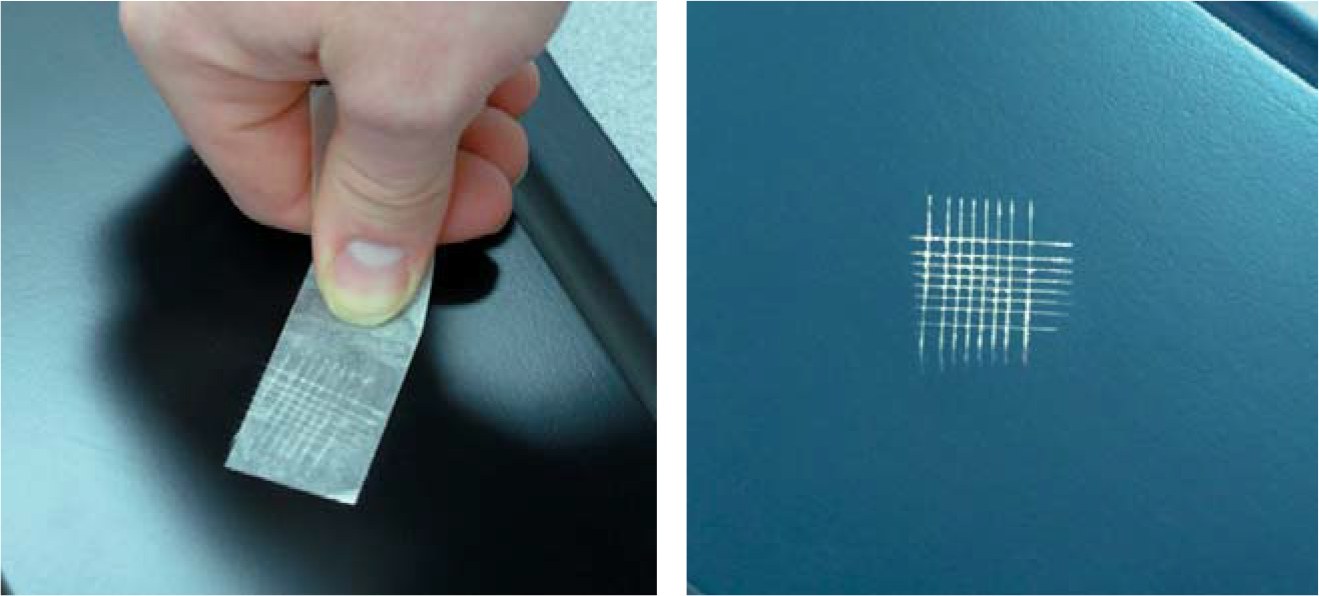

Problem: Using a hexa-functional monomer system, cross-cut peeling occurred on the aluminum plate.

Solution:Replaced some monomers with flexible structures (e.g., EOEOEA).

Added 2% phosphate ester adhesion promoter.

Sandblasted the aluminum plate and applied an epoxy primer.

Result: Adhesion level improved from 1B to 5B.

Case 2: Blistering and Peeling of Water-based Industrial Paint on Galvanized Steel

Problem: Blistering after damp heat test, adhesion level 3B.

Solution: Changed phosphating pre-treatment liquid to zirconium-titanium environmental treatment.

Added 0.8% silane coupling agent.

Extended room temperature leveling time and controlled film thickness to within 40μm.

Result: Adhesion improved to 4B, no significant blistering after damp heat water immersion.

5. Conclusion: Systemic Optimization is Fundamental

Adhesion improvement cannot rely on a single method. Material selection, substrate treatment, and application control must be systematically coordinated:

Starting from formulation design, provide "gripping" chemical/physical structures.

"Create conditions" through advanced surface treatment technologies.

"Realize value" through standardized coating processes.

Only with a clear understanding of the adhesion formation mechanism can problems be addressed in a targeted manner in actual production and engineering applications.

Previous Page

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-07-28

2025-07-28