Understanding the Essence of Coating Adhesion

Release time:

2025-07-28

In the coatings industry, adhesion issues are present throughout almost the entire product lifecycle. From R&D formulation, substrate selection, and surface treatment, to application, drying, and even aging evaluation, the quality of adhesion determines the lower limit of coating performance. This article will focus on the core mechanisms of "coating adhesion," outlining its influencing factors, types of failure, and basic evaluation methods.

1. What is Adhesion?

In coating science, "adhesion" refers to the bonding strength between the coating film and the substrate, often characterized in terms of energy, stress, or force. Mechanistically, it is not merely simple physical adsorption or mechanical interlocking, but a complex, multi-dimensional interaction system, including:

Physical adsorption forces (van der Waals forces, hydrogen bonds)

Chemical bonding (covalent bonds, ionic bonds, etc.)

Mechanical interlocking (surface roughness)

Interfacial diffusion

Stress dispersion effect (flexible intermediate layer or substrate buffering)

Adhesion is an interfacial property that depends not only on the chemical and physical structure of the coating itself but also significantly on the type and surface condition of the substrate.

2. Key Factors Affecting Adhesion

The formation and maintenance of adhesion involve multiple dimensions of materials science, interfacial chemistry, and application technology. The core factors are summarized as follows:

1. Substrate Surface Condition

Surface Cleanliness: Contaminants such as oil, moisture, and dust can hinder the true contact between the coating film and the substrate, reducing adhesion efficiency.

Surface Roughness (Mechanical Interlocking): Appropriate rough surfaces help enhance mechanical adhesion, but excessive roughness can lead to stress concentration.

Surface Energy Matching: Low surface energy substrates (such as PP, PE, PTFE, etc.) are difficult to adhere to and require primers, base coats, or flame/corona treatment to improve wettability.

2. Coating System Properties

Polarity and Functional Group Design: Polar functional groups containing hydroxyl, carboxyl, amine groups, etc., can form hydrogen bonds or chemical bonds with the substrate.

Molecular Weight and Crosslinking Density: Larger molecular structures or higher crosslinking density often result in stronger adhesion, but flexibility may decrease.

Flowability and Wettability: The spreading behavior of the coating film on the substrate surface determines whether it can fully contact and "stick".

3. Application and Curing Conditions

Temperature and Humidity: Substrate temperature being too low or environmental humidity being too high will affect the film-forming process, leading to insufficient adhesion.

Drying/Curing Rate: The film-forming speed of UV/EB, thermosetting, or air-drying systems varies, affecting the degree of interfacial penetration and reaction.

Application Method: Methods such as刮涂 (scraping), spraying, and rolling significantly impact film thickness and adhesion surface quality.

3. Main Manifestations of Adhesion Failure

Insufficient adhesion often manifests in the following forms of failure:

Failure Type | Description | Common Causes |

Peeling | The entire coating detaches from the substrate | Untreated surface, substrate contamination |

Blistering | Bubbles form under the coating film | Water penetration or residual solvent at the coating-substrate interface |

Cracking | Coating film cracks and peels due to internal stress | Uneven drying, excessive crosslinking, thermal expansion/contraction of substrate |

Delamination | Peeling between multiple coating layers | Insufficient crosslinking or mismatch of intermediate layers |

Additionally, there are aging and de-adhesion phenomena under complex conditions such as "boiling water peel-off," "cold impact peel-off," and "alternating damp heat peel-off".

4. Common Adhesion Test Methods

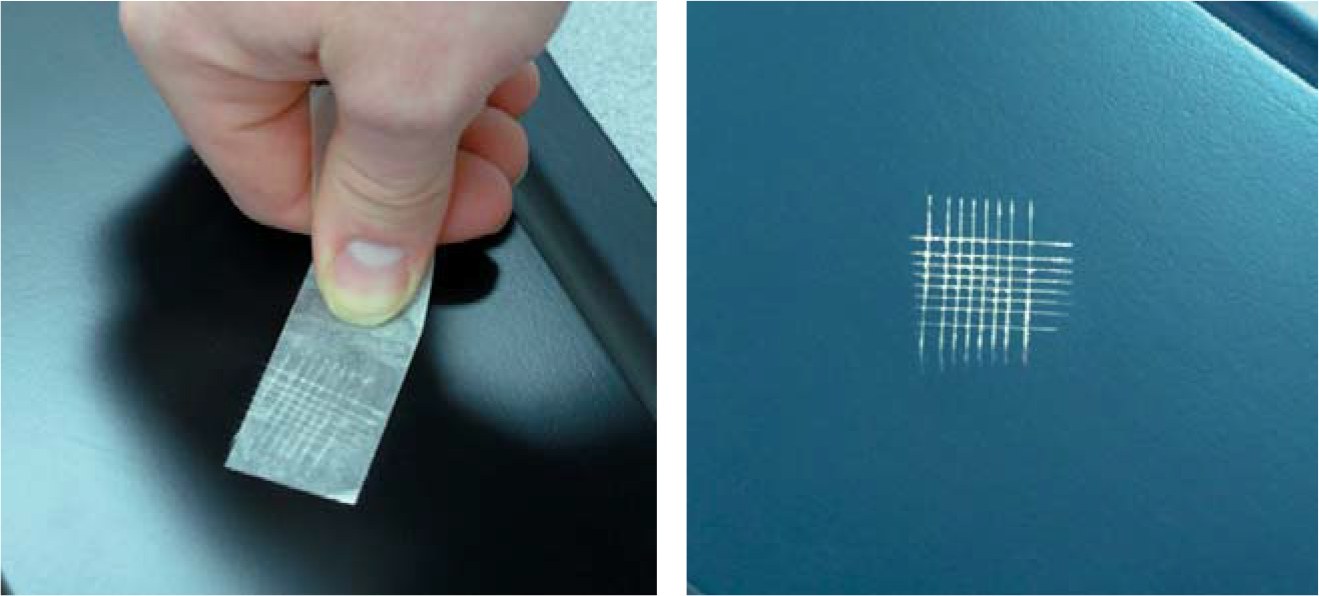

1. Cross-Cut Test

Standard: GB/T 9286 / ISO 2409

Principle: A grid is incised on the film surface, adhesive tape is applied and rapidly pulled off, and the degree of coating detachment is observed.

Advantages: Simple operation, suitable for quick on-site evaluation.

Limitations: Highly subjective, suitable for rigid substrates.

2. Pull-off Test

Standard: ISO 4624

Principle: A testing instrument vertically pulls off an aluminum dolly bonded to the coating film, recording the maximum pull-off force.

Advantages: Numerical data, suitable for horizontal comparison.

Limitations: High demands on the test surface, time-consuming.

3. Scratch Test

Applicable to hard films, such as UV coatings or PVD coatings, recording the force required to scratch through.

Can be combined with acoustic emission and friction change to accurately determine the interfacial failure point.

5. How to Scientifically Interpret Adhesion Data?

Adhesion testing has certain "interfacial randomness" and operational variability. It is recommended to analyze from the following perspectives:

Multi-method Verification: Comprehensive analysis of data from cross-cut, pull-off, and damp heat aging tests.

Trend Comparison: Focus on relative changes under different systems and surface treatment conditions.

Combined with Failure Analysis: Utilize methods such as SEM, FTIR, and XPS to track the structure of the peel-off surface and confirm whether the failure is at the substrate, interface, or within the coating film.

6. Summary and Reflection

Adhesion is far more complex than just a "pull force value". It is a comprehensive product of interfacial science and chemical reactions, requiring collaborative optimization from formulation engineers, application engineers, and quality control personnel. Understanding its mechanism is the first step in solving adhesion problems.

In the next article, "Formulation and Process Strategies for Improving Adhesion," we will further explore how to achieve more stable and excellent adhesion performance through formulation design, surface treatment, and application management.

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-07-28

2025-07-28