What is "Cross-linking"?

Release time:

2025-07-15

In the fields of polymer materials, coatings, adhesives, and even medical materials, you may often hear the term "cross-linking." So, what exactly is "cross-linking"? And why is it so important?

A one-sentence explanation of cross-linking:

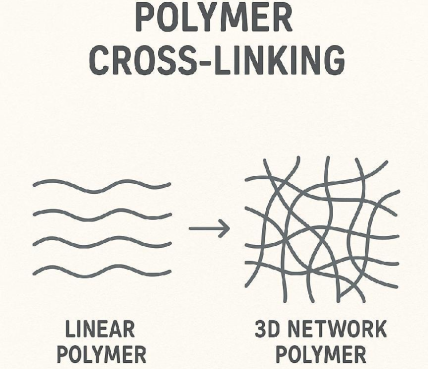

Cross-linking is the process by which "bridges" are formed between polymer chains, connecting the originally independent linear chains into a stable three-dimensional network structure.

From "Spaghetti" to "Lasagna": Understand it in seconds with a picture!

[Figure 1] Schematic diagram of Linear Polymer vs. Cross-linked Polymer structure

Imagine a bowl of cooked spaghetti – the noodles are separate, much like uncross-linked polymer chains, soft but easily deformable. But if you "stick" these noodles together with cheese and sauce and bake them into a lasagna, the structure becomes firm and strong; this is the effect of cross-linking.

Why Cross-link?

Before Cross-linking | After Cross-linking |

Soft, elastic but easily swellable | Stable structure, enhanced strength, not easily dissolved |

Easily deforms with heat | Improved heat resistance |

Solvents easily penetrate | Enhanced barrier properties |

Thermoplastic processing possible | Usually becomes a thermosetting material |

Summary: Cross-linking = A key step to enhance performance.

What are the methods of cross-linking?

1️⃣ Chemical Cross-linking (Irreversible)

Connects through covalent bonds, forming a strong network structure. Commonly found in:

Thermosetting resins

UV/EB curing systems

Adhesive curing processes

Characteristics: Stable, irreversible, once cured cannot be melted again.

2️⃣ Physical Cross-linking (Reversible)

Relies on non-covalent interactions such as hydrogen bonds, Van der Waals forces, and ionic bonds for connection. Commonly found in:

Gels

Thermoplastic elastomers

Characteristics: Reversible, flexible, can be hot-melted and reshaped.

Typical Application Scenarios for Cross-linking

Application Field | Benefits of Cross-linking |

UV Curing Coatings | Rapid curing, scratch resistance, insoluble |

Adhesives | Strong adhesion after curing, resistant to high temperatures |

Medical Hydrogels | Strong water retention, controllable degradation |

Tire Rubber | Strength and elasticity coexist, wear-resistant |

Super Absorbent Resins | Network structure determines water absorption and release performance |

Extended Knowledge: What is Cross-linking Density?

More cross-linking isn't always better. Cross-linking density refers to the number of cross-linking points per unit volume:

Too low density → Material too soft, unstable

Too high density → Too brittle, loses flexibility

Therefore, the appropriate degree of cross-linking needs to be "adjusted" for different industries and functional requirements.

✅ One-sentence summary:

"Cross-linking is like building a skeleton for polymer materials, transforming them from 'flimsy' to 'standing tall and firm'." It determines the material's "hardness, elasticity, durability, and stability," and is a crucial step for material performance leap.

Next Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-07-16

2025-07-16