Propoxylated Glyceryl Triacrylate (Easmer GPTA): Focusing on Bio-based Characteristics and Diverse Applications

Release time:

2025-06-23

Propoxylated Glyceryl Triacrylate (GPTA, CAS#52408-84-1), a trifunctional acrylate monomer, plays an increasingly important role in ultraviolet (UV) and electron beam (EB) curing technologies. It possesses not only the rapid curing and high cross-linking density typical of traditional acrylate monomers but also stands out due to its core skeleton being derived from bio-based glycerol, attracting significant attention amidst the global pursuit of sustainable development and green chemistry. GPTA offers a solution for developing high-performance photocurable materials that balance environmental benefits with excellent properties.

Structure and Product Specifications of Easmer GPTA

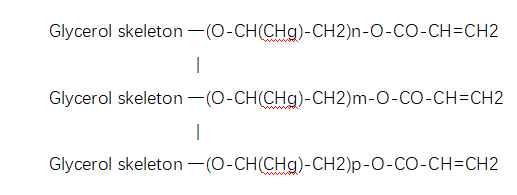

The molecular structure of GPTA is fundamental to its performance. Its core skeleton is derived from glycerol, a trihydric alcohol. The three hydroxyl groups of glycerol react with propylene oxide to undergo propoxylation, introducing flexible polyether segments. Subsequently, the terminal hydroxyl groups of these propoxylated segments undergo esterification with acrylic acid (or its derivatives) to form a molecule containing three acrylate functional groups. The degree of propoxylation (i.e., the average number of propylene oxide units attached to each glycerol molecule, typically expressed as moles of PO) can be controlled. Easmer GPTA products typically have a propoxylation degree of about 3.5 PO units.

This trifunctional structure enables GPTA, under the action of photoinitiators, to form a highly cross-linked three-dimensional network structure through free radical polymerization, which is the basis for its rapid curing and formation of tough coatings. Concurrently, the introduced propoxy segments impart a certain flexibility to the molecule, mitigating the brittleness issues that can arise with traditional high-functionality acrylates (such as trimethylolpropane triacrylate, TMPTA) after curing.

where n, m, p represent the number of propoxy units, and their sum is usually around 3-4.

Product Specification Parameters

Property | Value |

Appearance | Transparent liquid |

Color/APHA | 50 Max |

Viscosity/cps@25 ℃ | 70-110 |

Acid Value/ mgKOH/g | 0.5 Max |

Water Content/wt.% | 0.1 Max |

Inhibitor MEHQ /ppm | 500 Max |

Core Performance Advantages of Easmer GPTA

High Reactivity and Rapid Curing The GPTA molecule contains three acrylate functional groups. These double bonds can rapidly participate in free radical polymerization reactions when initiated by a photoinitiator under UV or EB radiation. This high reactivity directly translates to fast curing speeds, which is significant for improving production efficiency, shortening production cycles, and reducing per-unit energy consumption.

Excellent Flexibility and Film-forming Balance Compared to some traditional highly reactive trifunctional monomers (such as TMPTA), GPTA incorporates propoxy (PO) segments into its molecular structure. These polyether segments offer good flexibility, acting as "internal plasticizers" within the cured network, thereby significantly improving the flexibility of the cured film.

Low Skin Irritation Many traditional acrylate monomers have limited application due to their higher skin irritation and pose potential risks to operators' health. GPTA shows improvement in this regard and is described as having "low skin irritation" characteristics.

Good Pigment Wetting and Dispersion The molecular structure of GPTA, particularly its polyether segments, helps improve its ability to wet and disperse solid particles like pigments and fillers. Good wetting means the monomer can better encapsulate pigment particles, reducing interfacial tension, which in turn makes pigments easier to disperse uniformly in the resin system and less prone to settling or flocculation. This is crucial for preparing vibrant, uniform, and stable UV inks and paints, contributing to improved color development, gloss, and storage stability of products.

Traceability and Value of Bio-based Raw Materials The molecular backbone of Easmer GPTA products is modified from bio-based glycerol through propoxylation. Using bio-based glycerol derived from renewable resources instead of traditional petrochemical-based glycerol has significant strategic importance for reducing reliance on finite fossil resources, lowering greenhouse gas emissions (because biomass absorbs CO2 during growth), promoting the value-added utilization of agricultural and forestry waste, and advancing the development of a circular economy.

Application Scenarios of Easmer GPTA: Diverse Settings and Case Studies

Leveraging its comprehensive advantages such as rapid curing, good flexibility, low viscosity, low irritation, and bio-based origin, GPTA is widely used as a key reactive monomer or diluent in numerous industrial fields. It can not only enhance product performance but also improve process efficiency and environmental friendliness.

UV Coating Field UV coatings, with their high efficiency, environmental friendliness, and energy-saving characteristics, play an important role in surface treatment of various substrates such as wood, plastic, metal, and paper. GPTA primarily plays the following roles in UV coating formulations:

- Active Diluent: GPTA's low viscosity helps reduce the application viscosity of UV coating formulations, improving their fluidity and leveling, reducing or avoiding the use of volatile organic solvents (VOCs), making the coatings more environmentally friendly.

- Performance Modifier: It participates in the curing reaction, increasing the cross-linking density of the coating, thereby enhancing its hardness, wear resistance, chemical resistance, and adhesion. The introduced flexible segments can improve the coating's flexibility, preventing cracking.

- Curing Rate Promoter: As a trifunctional monomer, it can significantly increase the curing rate of the coating.

Detailed Application Scenarios and Case Analysis:

- Wood Coatings: Used for UV clear coats or colored paints on furniture, flooring, etc..

- Case: High-performance wood UV clear coat. The addition of GPTA can provide excellent scratch resistance and flexibility while ensuring the coating's fullness and high gloss, adapting to the moisture expansion and contraction of wood. Its rapid curing characteristic also meets the needs of modern furniture industry for efficient production.

- Plastic Coatings: Used for 3C product casings, automotive interior and exterior parts, cosmetic packaging, etc..

- Case: Automotive interior plastic parts UV topcoat. Automotive interior parts require high wear resistance, chemical resistance (e.g., to cleaning agents, sunscreens), and certain flexibility. GPTA helps the coating meet these performance requirements while achieving good adhesion with plastic substrates (such as ABS, PC) and is more favored due to its lower irritation.

- Metal Coatings: Such as coil coatings, and internal and external can coatings. GPTA can provide fast curing and good adhesion and corrosion resistance.

- Paper Overprint Varnishes: Used on printed surfaces to improve gloss, wear resistance, and protection. GPTA's low viscosity and fast curing are very suitable for high-speed overprinting processes.

UV Ink Field UV inks, due to their instant curing, solvent-free or low-solvent content, and high print quality, are widely used in packaging printing, commercial printing, label printing, and even special printing (such as circuit boards). GPTA's role in UV inks is similar to that in coatings, but with a greater emphasis on:

- Viscosity Adjustment and Rheology Control: Ink viscosity requirements vary for different printing methods (offset, screen, flexo, inkjet). GPTA's low viscosity helps formulate inks that meet requirements.

- Pigment Wetting and Dispersion: GPTA's good pigment wetting (Jiahua Chemicals) is crucial for ink color performance, stability, and printability.

- Curing Performance and Print Characteristics: Rapid curing adapts to high-speed printing; it imparts good adhesion, abrasion resistance, chemical resistance, and gloss to prints.

Detailed Application Scenarios and Case Analysis:

- Offset/Screen/Flexo Inks: Used for various substrates such as paper and plastic film.

- Case: Plastic film UV flexographic printing ink. Flexible packaging materials require inks to have good flexibility and adhesion to non-absorbent substrates. GPTA can provide this flexibility while ensuring rapid ink curing to prevent smudging.

- UV Inkjet Inks: Extremely strict viscosity requirements (usually <20mPa·s). GPTA, as a reactive diluent, helps reduce ink viscosity to a usable range while ensuring curing speed and durability of printed images.

UV Adhesives Field UV adhesives, characterized by fast curing, on-demand curing, high bonding strength, and good transparency, have important applications in electronic assembly, optical devices, medical devices, and labels. In UV adhesives, GPTA:

- Provides Fast Curing Capability: Enables "second-level" bonding, improving production efficiency.

- Adjusts Bonding Performance: Participates in the formation of a cross-linked network, affecting the adhesive's cohesive strength, peel strength, and shear strength.

- Improves Flexibility: GPTA's flexibility is crucial for bonding components that need to withstand vibration or thermal expansion and contraction.

Detailed Application Scenarios and Case Analysis:

- Electronic Component Bonding and Packaging: Such as chip fixation, circuit board component bonding.

- Case: Touch screen optical clear adhesive (OCA). OCA is used to bond various optical components of touch screens, requiring high light transmittance, low haze, fast curing, and good adhesion to glass, PET, and other substrates. GPTA can be part of the formulation, contributing to fast curing and final bonding performance, while its low volatility also benefits the clean production environment of precision optical components.

- Medical Device Assembly: Such as catheter and needle bonding. GPTA's low irritation may be an additional advantage in such applications (however, any medical application requires strict biocompatibility testing).

3D Printing (Additive Manufacturing) Field In photocuring 3D printing technologies (such as SLA, DLP, LCD), liquid photosensitive resin is cured layer by layer under specific wavelengths of light. GPTA is an important component in these photosensitive resin formulations:

- Reactive Monomer/Diluent: Adjusts the viscosity of the resin to ensure smooth printing and accuracy.

- Curing Speed and Forming Efficiency: GPTA's high reactivity helps improve printing speed.

- Mechanical Property Regulation: Affects the tensile strength, elongation at break, hardness, impact toughness, etc., of printed parts. Especially its imparted flexibility is very important for preparing flexible or semi-flexible parts.

- Engineering Prototype Manufacturing: Rapid manufacturing of prototypes with specific mechanical property requirements.

- Case: Engineering flexible 3D printing resin. Certain application scenarios (such as prototypes for buckles, seals, shock absorbers) require printed parts to have certain flexibility and tear resistance. GPTA can be combined with other monomers and oligomers (such as polyurethane acrylates). By adjusting its proportion in the formulation, 3D printed parts with different mechanical properties ranging from semi-rigid to highly flexible can be prepared.

Electronic Chemicals and Other Emerging Applications In addition to the mainstream applications mentioned above, GPTA's properties give it potential for use in some emerging or specialized electronic chemical fields:

- Photoresists: In microelectronics manufacturing, photoresists are used for pattern transfer. UV-curable photoresists require high resolution, fast curing, and good developing performance. GPTA's reactivity and film-forming properties may enable it to find application in specific types of photoresist formulations.

- Electronic Encapsulation Materials and Conformal Coatings: Used to protect sensitive electronic components from moisture, dust, chemicals, and mechanical stress. GPTA can provide fast curing, good insulation, and certain flexibility.

- Biomedical Materials: Although GPTA itself claims low irritation, any biomedical material used for direct human contact or implantation must undergo extremely strict biocompatibility, cytotoxicity, and other series of evaluations and certifications. Its bio-based origin may provide a starting point for exploring more sustainable medical materials, but this requires extensive specialized research.

- Exploratory Analysis: GPTA's application in these cutting-edge fields mainly relies on further optimization of its performance (such as ultra-low ion content, extremely low curing shrinkage) and effective compounding with other functional materials. Its bio-based origin brings a sustainability label, which may become an additional competitive advantage in some precision electronics or high-end consumer product fields that have high environmental friendliness requirements.

Trends and Development Against the backdrop of increasingly stringent global environmental regulations and rising consumer awareness of green products, the bio-based chemical market is experiencing unprecedented development opportunities. GPTA, as a member of this market, has significant future potential:

- Deepening and Expanding Applications:

- Existing Fields: In traditional advantageous fields, GPTA will further replace traditional solvent-based products or monomers with insufficient performance due to its performance and environmental characteristics.

- Emerging Fields: Exploration in biomedical (requiring strict certification), smart materials, high-performance composite materials, flexible electronics, and other cutting-edge fields is expected to open up new growth points for GPTA. For example, its flexibility and bio-based origin may give it potential in wearable devices and biosensors.

- Existing Fields: In traditional advantageous fields, GPTA will further replace traditional solvent-based products or monomers with insufficient performance due to its performance and environmental characteristics.

- Technology-driven Innovation:

- Increasing Bio-based Content: By using bio-based propylene oxide, bio-based acrylic acid, and other raw materials, or optimizing synthesis routes, it is expected to further increase the overall bio-based content of GPTA, strengthening its green attributes.

- Green Synthesis Processes: Developing more efficient, atom-economical synthesis processes that use fewer harmful solvents and catalysts to reduce the environmental footprint of the production process.

- Performance Customization and Functionalization: By precisely controlling the degree of propoxylation, introducing other functional groups, etc., to develop GPTA derivatives with specific properties (such as higher flexibility, lower odor, self-healing capability, antibacterial properties, etc.) to meet more segmented and high-end market demands.

- Increasing Bio-based Content: By using bio-based propylene oxide, bio-based acrylic acid, and other raw materials, or optimizing synthesis routes, it is expected to further increase the overall bio-based content of GPTA, strengthening its green attributes.

bio-based,GPTA

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-06-25

2025-06-25