UV Monocoat: Is a monocoat replacing a dual process a technological revolution or a limited breakthrough?

Release time:

2025-08-11

Introduction: The "Fast-Forwarded" Coating Production Line

Upon entering a certain home appliance casing factory, you'll see a comparison like this:

Traditional Production Line: Substrate → Primer spray coating → Bake for 30 minutes → Sanding → Topcoat spray coating → Second bake → Quality inspection

UV Monocoat Production Line: Substrate cleaning → Single-layer spray coating → 10-second UV curing → Direct packaging

This technology, which combines coloring and protection, is rapidly gaining popularity in the consumer electronics and home appliance sectors. But is it a cure-all solution?

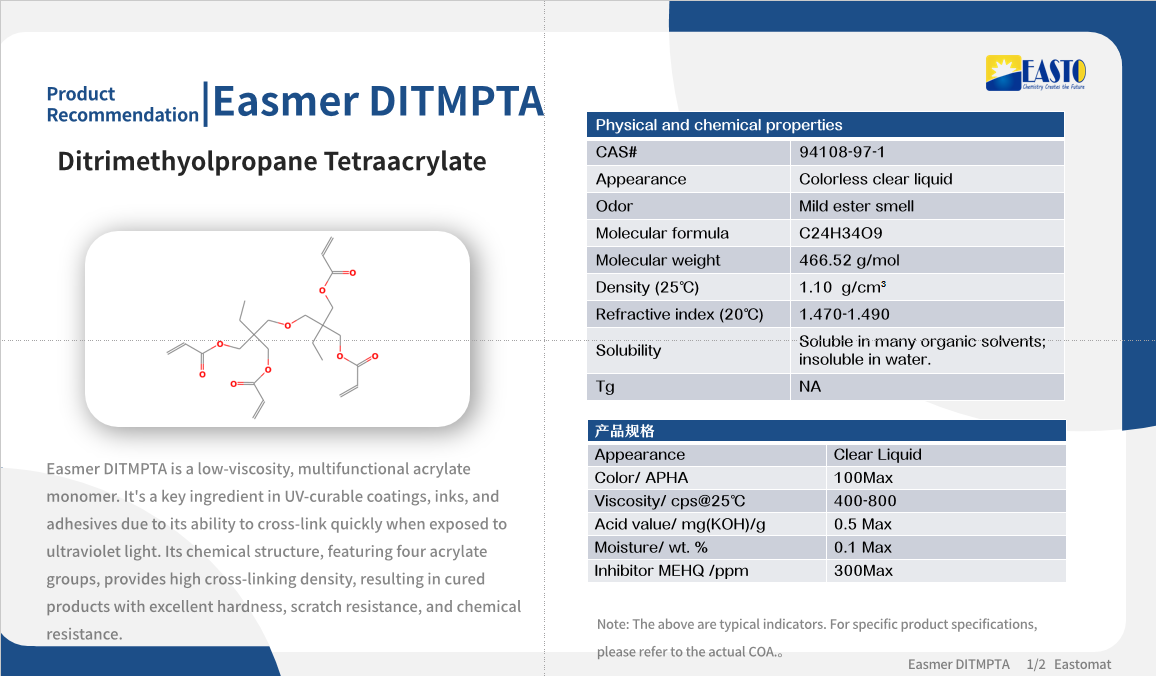

1. The Technical Essence: How does ultraviolet light achieve "two-in-one"?

The core breakthrough of UV Monocoat lies in using "photochemical reaction to replace thermal curing".

Formula Design:

Photosensitive resin (responsible for film formation and hardness)

Encapsulated pigments (provide primer-like opacity)

Active monomers (improve leveling)

<5% solvent (traditional coatings contain 30-60% solvent)

Second-level Curing: Ultraviolet light triggers photoinitiators to cleave, initiating a cross-linking reaction in the resin, forming a dense network structure in 3-10 seconds (traditional baking requires 20-40 minutes).

Key Indicator: A UV energy density of 800-1500 mJ/cm² is the threshold for complete curing.

2. Why are companies rushing to adopt it? Four real advantages

30% Direct Cost Reduction: Eliminates primer materials + reduces energy consumption from baking. For example, a mobile phone case factory saves 120,000 yuan in electricity costs per month.

Strong Environmental Compliance: VOC emissions are <50g/L (national standard limit is 420g/L). It has passed EU REACH certification.

Doubled Production Efficiency: Production line speed increases from 3m/min to 15m/min. A television panel factory saw a 400% increase in capacity.

Outstanding Physical Performance: Hardness of 2H-3H, abrasion resistance of 1000+ cycles (RCA test). Laptop casings have no scratches for life.

3. Three Overlooked Challenges: The Gap Between Ideal and Reality

1. A Narrow Process Window, like walking a tightrope

Film Thickness Tolerance <5μm: If the thickness exceeds 30μm, curing is insufficient (the bottom is sticky), while a thickness below 15μm results in a loss of opacity.

Strict Substrate Cleanliness Requirements: Fingerprints or mold release agent residue directly lead to craters (a 15-20% decrease in yield).

2. Hard Boundaries for Application Scenarios

✅ Applicable Scenarios | ❌ Risk-of-Failure Scenarios |

• Flat/shallow curved plastic parts | • Deep cavity structures (UV light blind spots) |

• Light colors (low opacity requirements) | • Pure black/metallic colors (require film thickness >6μm) |

• ABS/PMMA/HIPS substrates | • Non-polar materials like polypropylene (PP) |

3. Hidden Cost Traps

UV-LED equipment investment is 3-5 times that of a traditional oven (1 million yuan vs. 200,000 yuan).

When pigments cause incomplete curing, special dispersing agents must be added (increasing costs).

4. The Industry Truth: Who's using it? How?

Commonalities of Successful Cases

Consumer Electronics: Mobile phone back panels (flat + medium-light colors) → Key Strategy: Paired with plasma pretreatment to improve adhesion.

Appliance Panels: Air conditioner control panels (small area, high-gloss requirements) → Innovative Solution: Local UV curing replaces overall spray coating.

Lessons from Failures

A car company attempted to use it for car gear shifts.

Reason for Failure: The curved surface led to uneven curing → Edges peeled off after three months.

Solution: Reverted to a hybrid process of "UV primer + water-based topcoat".

5. Future Breakthrough Directions: Beyond "Single-Layer"

Composite Curing Technology: UV pre-curing + 80℃ post-thermal curing (solves the shadow area problem).

Water-based UV Monocoat: Solvent content is close to 0 (BASF has launched an experimental product).

Intelligent Light Source System: Dynamically adjusts wavelengths to suit different pigments (e.g., titanium dioxide needs 365nm, carbon black needs 395nm).

Conclusion: A Rational View of Technological Innovation

"UV Monocoat is not a panacea, but an efficient tool for specific scenarios. It is the optimal solution when you are pursuing ultimate efficiency and environmental protection on flat, light-colored plastic parts. If you force it to cover complex conditions, you will pay a higher price."

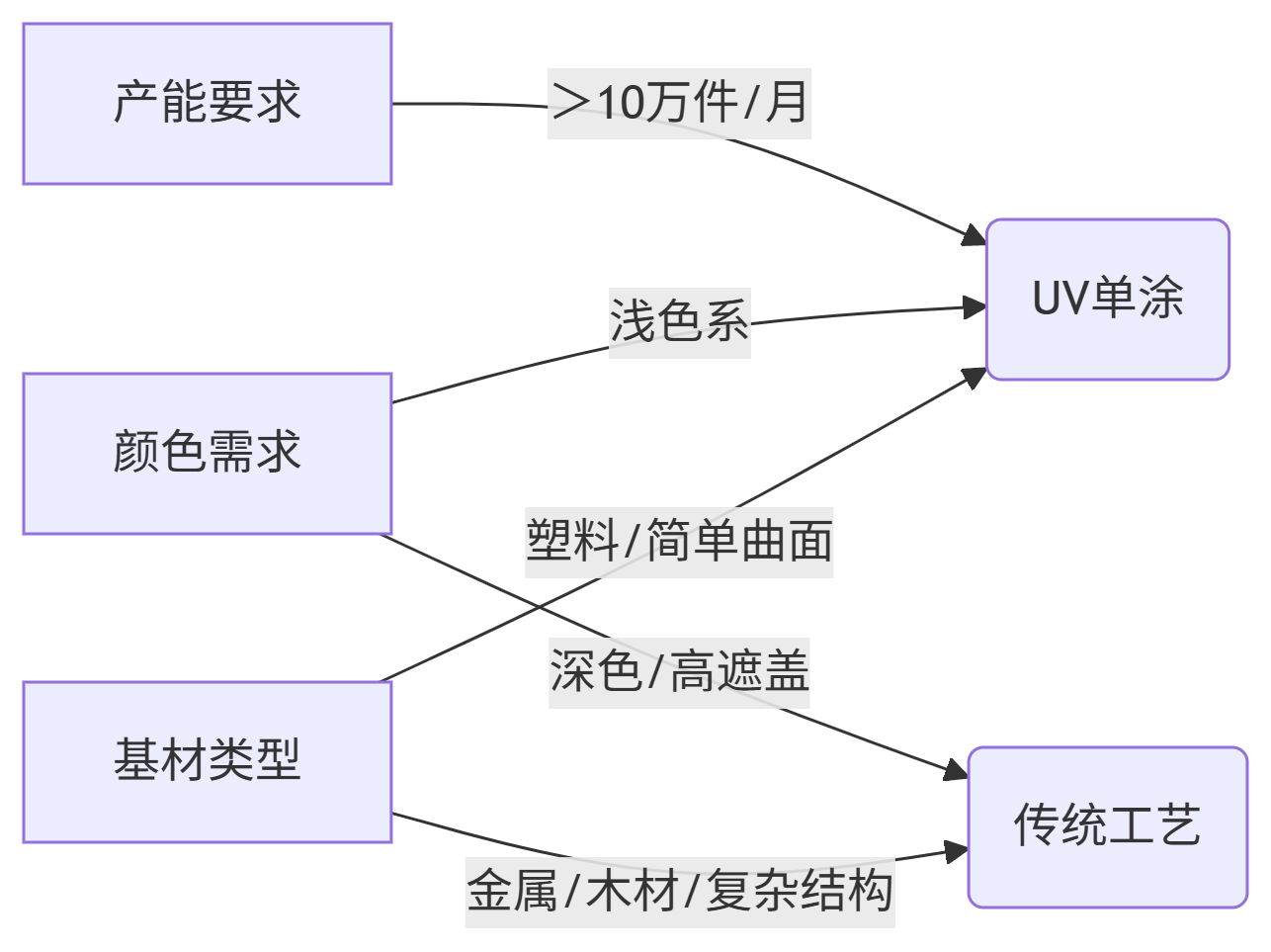

Technology Selection Recommendations:

Previous Page

Next Page

Previous Page

Next Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-08-11

2025-08-11