High Refractive Index Monomer — Easmer OPPEA

Release time:

2025-08-04

Product Overview

o-Phenylphenoxyethyl Acrylate (OPPEA, CAS# 72009-86-0) is a high-performance mono-functional UV-curable reactive diluent. Its unique molecular structure—featuring a biphenyl group and a flexible ethoxy chain—imparts a range of exceptional properties, making it a key ingredient in optics, electronics, and advanced manufacturing.

The most notable characteristics of OPPEA include its very high refractive index, excellent balance between flexibility and surface hardness, low volatility, low odor, and low skin irritation. As a diluent in UV-curable resins, it not only effectively reduces system viscosity, but also significantly enhances the optical performance, chemical resistance, and dimensional stability of the cured product. As an advanced UV monomer, OPPEA is widely used in high-end optical coatings, 3D printing materials, and electronic photoresists.

Chemical Name: o-Phenylphenoxyethyl Acrylate

CAS Number: 72009-86-0

Molecular Formula: C₁₇H₁₆O₃

Molecular Weight: 268.31 g/mol

Key Performance Indicators

The following data summarizes the core physicochemical properties and typical product specifications of OPPEA, serving as a reference for formulation design and process control.

Physicochemical Properties

Item | Value / Description |

Appearance | Colorless to pale yellow transparent liquid |

Odor | Slight characteristic odor |

Density (25°C) | ≈1.15 g/cm³ |

Glass Transition Temp. | ≈33 °C |

Boiling Point (1 mmHg) | ≈180–190°C (under reduced pressure) |

Flash Point | >110°C (closed cup) |

Refractive Index (nD²⁵) | ≈1.56–1.58 |

Solubility | Soluble in organic solvents like acetone, ethanol, ethyl acetate; insoluble in water |

Reactivity | Contains acrylate groups, easily undergoes radical polymerization |

Product Specifications

Item | Specification |

Appearance | Transparent liquid |

Color / APHA | 100 Max |

Viscosity / cps@25°C | 120–150 |

Acid Value / mgKOH/g | 0.5 Max |

Moisture / wt.% | 0.2 Max |

Inhibitor (MEHQ) / ppm | 300 Max |

Core Application Areas

Thanks to its unique property set, OPPEA demonstrates excellent application value in several high-tech fields.

Optical Materials and Precision Optics

OPPEA is an ideal choice for manufacturing high-refractive-index optical materials. With a refractive index up to 1.576, it significantly enhances the light control capability of optical components and reduces Fresnel reflection losses, thereby improving light transmission efficiency.

AR/VR Lenses and Optical Adhesives: As a reactive diluent in UV adhesives, OPPEA maintains high transparency (>98%) while improving flowability, making it suitable for the production of augmented reality (AR), virtual reality (VR) lenses, and anti-reflective films for smartphones. Its use significantly enhances display brightness and clarity.

Optical Films: Applied in brightness enhancement films (BEF) for LCD backlight modules to effectively converge light and increase screen brightness.

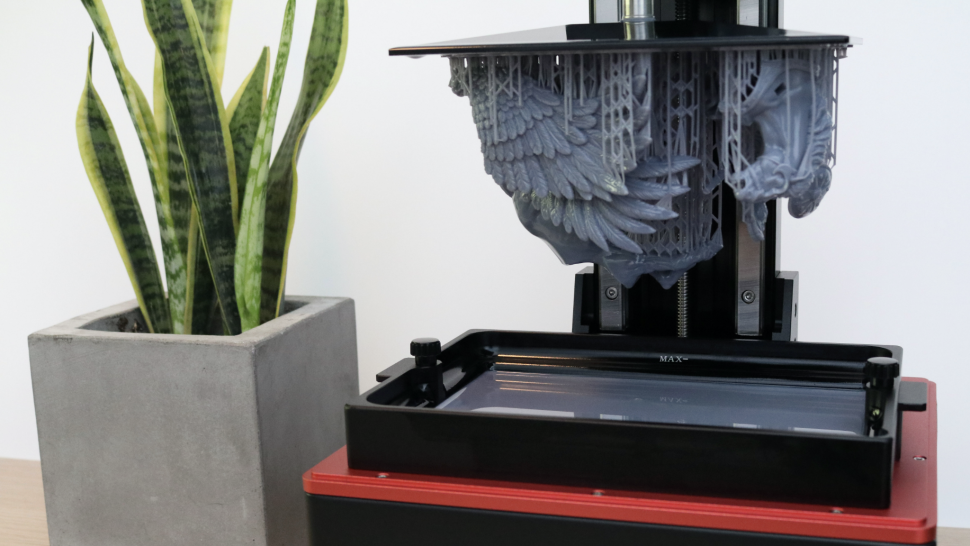

3D Printing and Additive Manufacturing

In light-curing 3D printing technologies (e.g., SLA, DLP), OPPEA's low curing shrinkage (<3%) is critical for ensuring dimensional accuracy of printed parts, especially for producing micro-optical components and complex structures.

In the additive manufacturing of advanced ceramics, OPPEA plays a key role. Ceramic powders such as aluminum nitride (AlN) and silicon nitride (Si₃N₄) have much higher refractive indices than typical resins, leading to severe light scattering, limiting curing depth and accuracy. Incorporating high-refractive-index OPPEA helps reduce the refractive index mismatch (Δn) between resin and ceramic powder, thus increasing curing depth, suppressing scattering, and enabling the production of high-performance ceramic parts with better structural integrity.

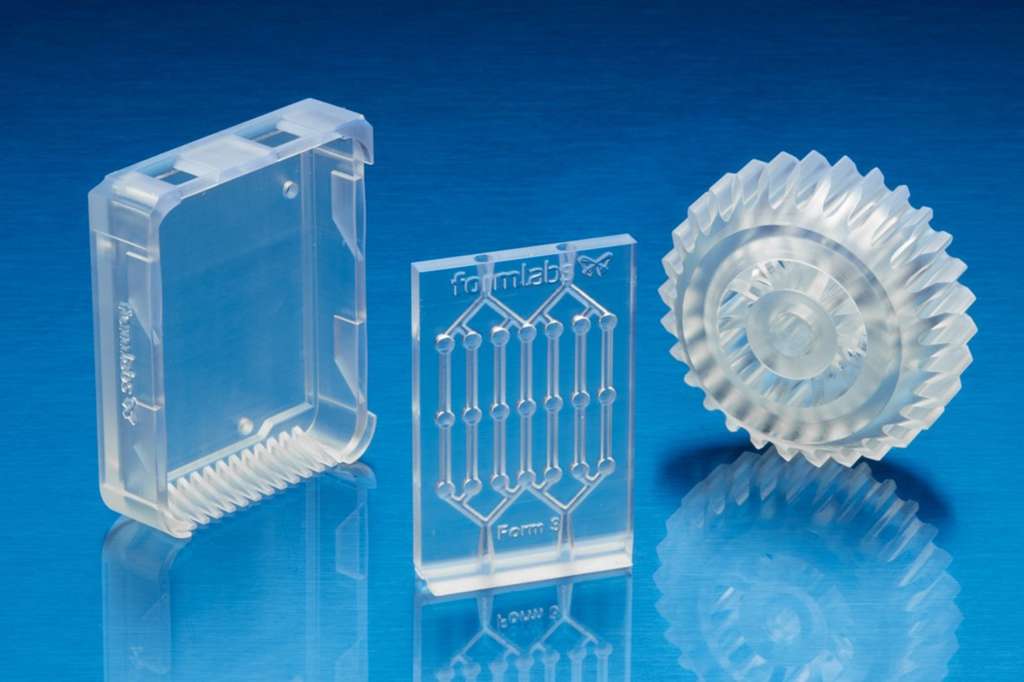

Example: High-precision transparent parts made by SLA demonstrate potential in microfluidic chips and complex mechanical structures.

Electronics and Semiconductors

Thanks to its high reactivity and excellent chemical resistance, OPPEA is an ideal material for the electronics industry.

Photoresists for Electronics: In semiconductor and display manufacturing, OPPEA can be formulated into photoresists to achieve high-resolution pattern transfer. Its strong adhesion and chemical resistance provide reliable circuit protection.

Flexible Circuits and Packaging: Its cured products offer both flexibility and protection, making it suitable for protective coatings on flexible printed circuit boards and packaging materials for semiconductor chips.

High-Performance Coatings and Inks

As a multifunctional monomer, OPPEA is widely used in UV-curable coatings and ink systems to enhance gloss, durability, and adhesion.

UV Coatings: Suitable for surface coatings on wood, plastic, and metal, providing high gloss, scratch resistance, and chemical resistance. Its good dilution ability helps adjust coating viscosity for different application processes.

UV Inks and Overprint Varnishes: In the printing industry, OPPEA is used to formulate UV inks and varnishes, improving wear resistance and gloss.

Other Applications: Also applicable in high-end UV nail polishes, waterborne UV coatings, and other specialty areas.

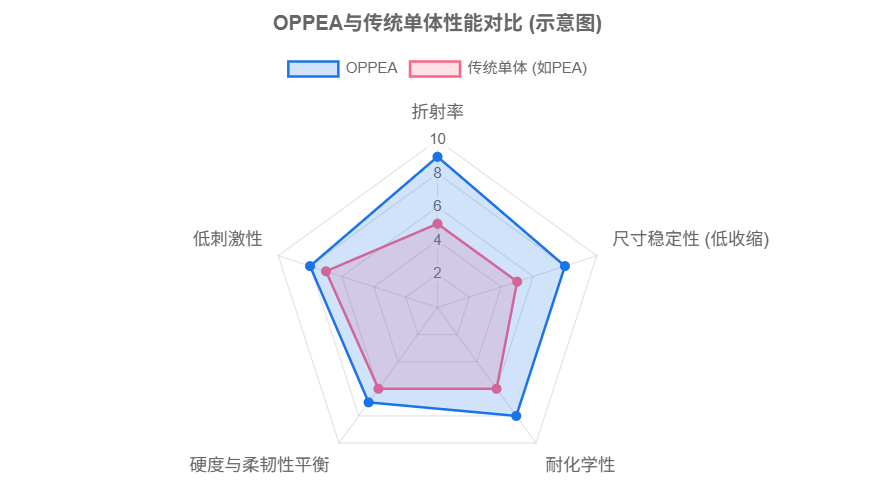

Performance Comparison: Easmer OPPEA vs. Mono-Aromatic Acrylate Monomers

Compared to traditional mono-aromatic acrylate monomers (e.g., phenoxyethyl acrylate, PHEA), OPPEA’s unique biphenyl structure offers significant advantages in several key performance metrics, making it more competitive in high-end applications.

Data Insight: The biphenyl structure of OPPEA significantly increases the refractive index and thermal stability after curing. Its larger molecular size helps reduce volumetric shrinkage during curing, resulting in better dimensional stability. Patent studies have shown that monomers with more aromatic groups reduce cure shrinkage and improve thermal stability compared to single-ring acrylates.

Contact Us

Eastomat is a company dedicated to R&D, production, and sales of high-performance chemical materials. We strive to deliver innovative, high-quality products and solutions to meet the evolving needs of the market.

Website: www.eastomat.com

Email: sales@eastomat.com

Phone: +86-13921698030

WeChat: Search “屹东材料 EASTOMAT”

LinkedIn / Facebook: Search “EASTOMAT”

OPPEA

Previous Page

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-08-04

2025-08-04