The Polymer Mood Swing: What is Tg and Why Does It Matter?

Release time:

2025-07-02

In the world of polymers, there’s a mysterious turning point—a temperature that transforms a material’s personality. Cross this line, and your plastic buddy may go from rigid and brittle to stretchy and bouncy. This magical temperature is called the Glass Transition Temperature, or simply Tg.

Sounds like a puberty moment for materials? Pretty much. Tg is that precise temperature where a polymer “lets loose.”

Wait, is Tg the same as melting point?

Let’s clear this up first: Tg is not the melting point.

Melting point is where crystalline materials (like ice or metals) go from solid to liquid.

Tg, on the other hand, applies to amorphous or semi-amorphous polymers—like plastics and resins—and marks the transition from a glassy state to a rubbery state.

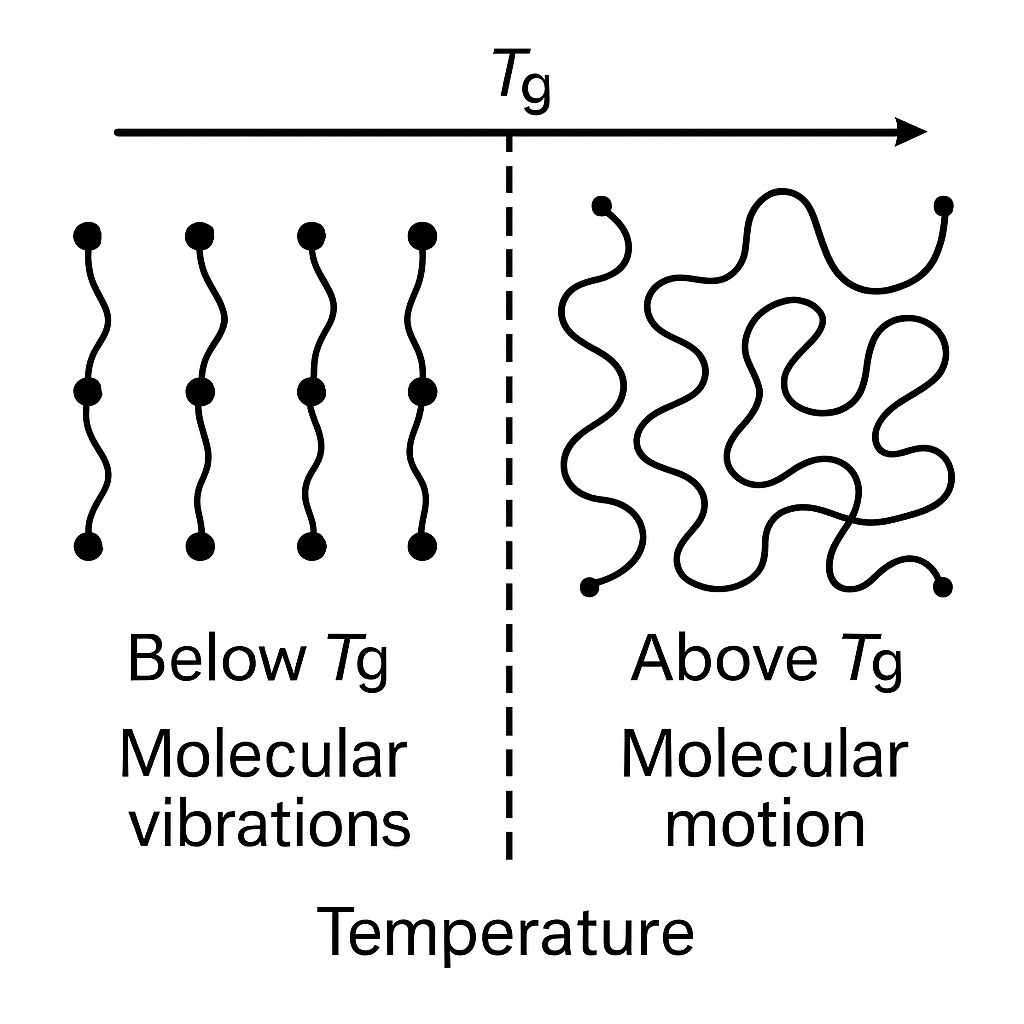

Below Tg, the polymer chains are frozen—like people stuck in a crowded subway. Above Tg, they start moving, dancing, and doing the cha-cha.

So, Tg is the moment a polymer starts to "loosen up."

Why does Tg matter?

This “mood swing” isn’t just fun science—it determines how the material performs, behaves, and even how long it lasts. Let’s see how Tg affects real-world properties:

1. Mechanical Behavior Transforms

Below Tg: The material behaves like glass—hard, brittle, and stiff. Think of a plastic ruler that snaps easily when frozen.

Above Tg: It becomes like rubber—soft, elastic, and flexible.

Example: PMMA (acrylic) has a Tg around 105°C. Below that, it’s tough and clear. Go above it, and it starts softening and warping.

2. Thermal Stability Depends on Tg

You don’t want your car’s dashboard to sag on a hot day, right? That’s why the materials used must have a Tg well above ambient temperatures.

High-performance materials like polyimides (PI) have Tg values over 250°C—for extreme environments.

3. Processing vs. Performance

This is the classic trade-off:

Low Tg → easy to process, soft, moldable;

High Tg → better in-use performance, but harder to shape.

Engineers must strike the right balance during formulation.

What Affects Tg?

Polymer scientists have a whole toolkit to tweak Tg:

Factor | Impact on Tg |

Flexible polymer chains | Lowers Tg (chains move easily) |

Strong intermolecular forces (e.g. hydrogen bonding) | Raises Tg (chains resist motion) |

High branching or crosslinking | Raises Tg (more rigid structure) |

Plasticizers | Lower Tg (act like molecular lubricants) |

So, even the same base polymer can have very different Tg values, depending on formulation.

Real-world Applications of Tg

Coatings: Tg affects film hardness and flexibility. Too low, and the coating stays tacky; too high, and it may crack.

3D Printing Resins: If Tg is too low, printed objects may deform in summer heat.

Packaging Films: Tg must be higher than storage temperatures to maintain sealability.

Electronic Adhesives: Tg affects whether they hold up under heat or flow away under pressure.

Simple Animation Analogy

Imagine polymer chains are people in a crowd:

Below Tg: They’re frozen stiff, barely able to move—think rush hour in a winter subway.

Above Tg: Everyone starts dancing and moving freely.

Go even higher: It turns into a rave—chains flow like a liquid, nearing melting point.

In Summary

Tg isn’t just a number—it defines the material’s personality:

Too low, and it’s like marshmallow: soft and sticky.

Too high, and it’s like glass: hard and brittle.

Just right, and you get the ideal combo of formability + durability.

So next time you see “Tg = 80°C” in a data sheet, know that this is the material’s critical “mood swing moment”—and could be the key to your product's success.

Want to explore more secrets of material science? Follow us for a closer look into the fascinating world of polymers!

Tg

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-07-02

2025-07-02