Polyethylene Glycol Diacrylate (PEGDA) – Structure and UV-Curable Applications

Release time:

2025-05-28

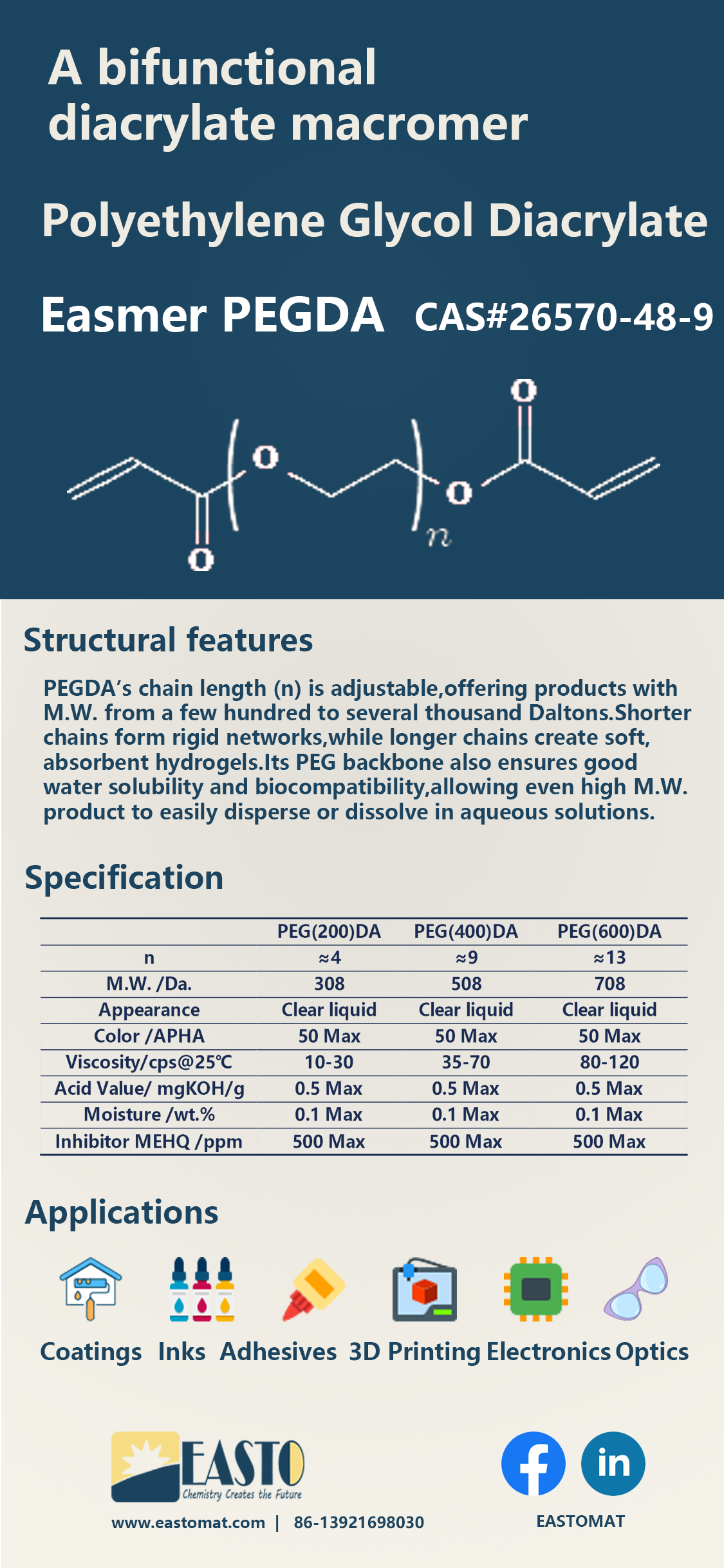

Structure and Chemical Features: PEGDA is a bifunctional diacrylate macromer with the formula H₂C=CHCO(OCH₂CH₂)_nO₂CCH=CH₂. In other words, it consists of a poly(ethylene glycol) (PEG) chain capped at both ends by acrylate groups. The terminal acrylate double bonds enable rapid free-radical photopolymerization, while the PEG backbone imparts hydrophilicity and flexibility. The length of the PEG chain (value of n, roughly 1–500 ethylene oxide units) is tunable; common commercial grades range from a few hundred to several thousand Da. Lower-molecular-weight PEGDA (short chains) yields dense, highly crosslinked networks, whereas higher-molecular-weight PEGDA produces more flexible, high-swelling gels. These variations allow formulators to adjust crosslink density and mechanical modulus. Importantly, the PEG backbone makes PEGDA water-soluble and biocompatible, so even high-MW formulations often dissolve or disperse in aqueous formulations.

UV Crosslinking Behavior: PEGDA cures by free-radical polymerization of its acrylate end groups under UV light. In the presence of a photoinitiator and UV irradiation, radicals are generated and rapidly react with the terminal C=C bonds. This “chain-growth” reaction links PEGDA molecules into a three-dimensional network. As radicals add to acrylates, covalent crosslinks form between PEG chains, building a solid hydrogel or coating. The resulting network gains mechanical strength and dimensional stability. Crosslink density (and thus stiffness, modulus, and swelling ratio) is controlled by PEGDA concentration and molecular weight: shorter PEGDA chains (more acrylate end-groups per unit weight) give stiffer, low-swelling polymers, while long-chain PEGDA yields softer, high-water-content networks. Notably, UV curing of PEGDA can occur rapidly at room temperature with low energy input, a feature prized for microfabrication and 3D-printing processes.

Mechanical and Optical Properties: The cured networks are typically transparent and colorless, with refractive index around 1.46polysciences.com. This optical clarity makes PEGDA hydrogels and coatings useful in photonic and microfluidic devices. PEGDA-based materials are generally elastic and tough when highly crosslinked, but become very soft and compliant at high water content (in hydrogels). The mechanical modulus can be tailored over a wide range by choosing the PEGDA grade and blend ratio. In coatings and adhesives, even small PEGDA segments can enhance flexibility and wet adhesion due to the hydrophilic, tacky nature of the PEG chainspolysciences.compolysciences.com. At the same time, the acrylate chemistry ensures cured PEGDA networks are solvent-resistant and stable. Many formulations include small amounts of multifunctional acrylates or nanofillers to further boost strength or abrasion resistance without compromising the inherent optical clarity.

Applications in UV-Curable Hydrogels and Coatings: PEGDA is widely used in UV-curable formulations across biomedical, printing, and industrial sectors. Key application areas include:

Biomedical Hydrogels: PEGDA forms “blank slate” hydrogels for tissue engineering scaffolds, wound dressings, and drug delivery matrices. Its biocompatibility and tunable swelling allow precise control of nutrient transport and cellular mechanics. Rapid UV cure enables patterning microgels or complex structures (e.g. by stereolithography) while encapsulating cells or bioactive agents with minimal heat stress.

3D Printing/Resins: As a photocurable resin component, PEGDA is a staple in stereolithography and digital light processing (DLP). Its diacrylate functionality and low viscosity (depending on MW) yield high-resolution prints with controllable stiffness. Adjusting PEGDA content tailors the cured polymer’s modulus and swelling, which is useful for making flexible hinges or porous scaffolds in a single print.

Coatings and Adhesives: PEGDA-modified coatings benefit from improved flexibility, adhesion, and water resistancepolysciences.compolysciences.com. In UV-cured flooring, varnishes and encapsulants, PEGDA provides toughness without brittleness. It also imparts hydrophilic surface properties, useful for biomedical device coatings or ink formulations. A range of applications (dental composites, inks, varnishes and flexible coatings) leverage PEGDA’s ability to form clear, robust filmspolysciences.com.

Optical and Electronic Materials: Due to its transparency and well-defined refractive index, PEGDA is used in optical sensors, microfluidic chips, and hybrid devicespolysciences.compolysciences.com. Crosslinked PEGDA films and waveguides exhibit low birefringence and stable optical properties. In photopolymerized nanoparticles or photonic structures, PEGDA’s high-fidelity curing yields smooth, defect-free components.

In summary, PEGDA’s combination of acrylate reactivity and PEG-derived hydrophilicity makes it a versatile UV-curable monomer. Its structure–property relationship is well understood: acrylate end-groups drive rapid crosslinking, while the PEG chain length governs flexibility, swelling, and biocompatibility. These features enable PEGDA to serve as a “tunable building block” in advanced coatings, biomedical hydrogels, adhesives, and photopolymer resins.

PEG200DA,PEG400DA,PEG600DA

Previous Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-05-29

2025-05-29