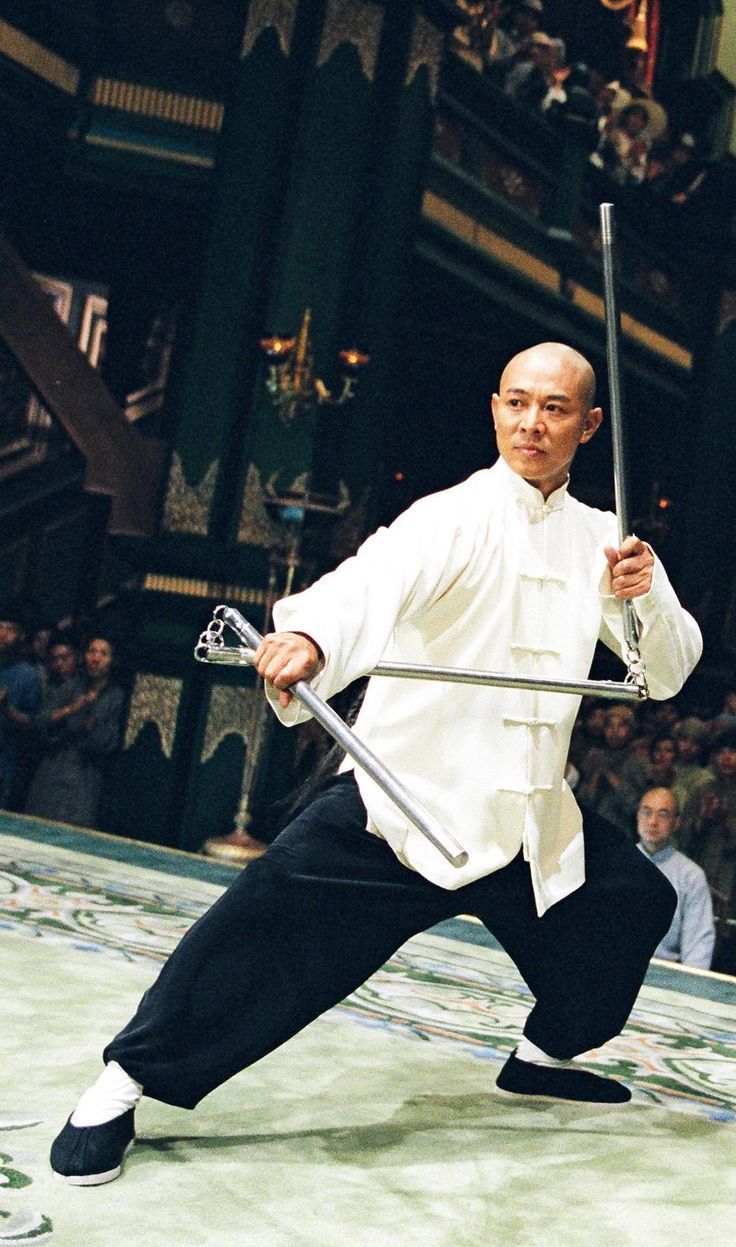

Unleash the Power of the "Three-Section Staff": Ethoxyethoxyethyl Acrylate (EOEOEA, CAS# 7328-17-8)

Release time:

2025-05-05

In the realm of functional acrylates, Ethoxyethoxyethyl Acrylate (EOEOEA, CAS# 7328-17-8) is increasingly becoming the focus of attention for many formulation engineers, driven by the growing demand for low viscosity, high flexibility, and excellent compatibility. This article will delve into the performance characteristics and broad application potential of EOEOEA, starting from its unique molecular structure.

I. Structural Characteristics and Performance Advantages of EOEOEA

EOEOEA, with the chemical name ethoxyethoxyethyl acrylate, has the molecular formula:

Structurally, EOEOEA features a special side chain connected to the oxygen atom of the ester group, consisting of two repeating ethoxy (-CH₂CH₂O-) units and an ethyl (-CH₂CH₃) group. This structure resembles a flexible "three-section staff." This unique structure endows EOEOEA with a series of distinctive properties:

Exceptional Flexibility

The ethoxy chains provide excellent molecular chain flexibility, resulting in cured materials with enhanced bending resistance and impact toughness, significantly reducing the risk of brittleness.

Low Viscosity

EOEOEA exhibits very low inherent viscosity and can be used as a highly effective reactive diluent. It helps to reduce the overall viscosity of formulations, improve workability and flowability, and minimizes the introduction of volatile organic compounds (VOCs).

Outstanding Compatibility

Thanks to its molecular structure with a balanced hydrophilic-lipophilic nature, EOEOEA demonstrates good compatibility with various types of resin systems, such as epoxy acrylates and polyurethane acrylates, ensuring formulation uniformity and stability.

Delicate Balance of Hydrophilic and Hydrophobic Properties

The ethoxy units possess a degree of hydrophilicity, enabling them to form hydrogen bonds with water molecules and enhance the water absorption and wettability of polymers. Conversely, the terminal ethyl group contributes a degree of hydrophobicity. This clever balance of hydrophilic and hydrophobic properties gives EOEOEA-based polymers unique advantages in interfacial properties, such as improved leveling in coatings and enhanced pigment dispersion.

II. Application Areas Analysis

Based on its excellent performance characteristics, EOEOEA demonstrates wide-ranging application value in multiple industry sectors:

✅ UV/EB Curing Coatings

In coatings for furniture, plastics, metals, and 3C electronic products, EOEOEA can be used as a reactive diluent to help control system viscosity, enhance film flexibility and adhesion, and reduce shrinkage and internal stress, thereby improving impact resistance.

✅ UV Inks

In UV flexographic printing, inkjet printing, and screen printing ink formulations, EOEOEA not only reduces ink viscosity and improves leveling but also enhances the adhesion between the ink and the substrate. It is particularly suitable for high-end applications such as flexible packaging and label printing.

✅ Photosensitive Resins and 3D Printing

In photosensitive resins and 3D printing materials for DLP and SLA processes, EOEOEA helps improve printing accuracy by reducing system viscosity and enhancing flowability. Additionally, its flexible chain segments can increase the impact resistance and toughness of printed parts.

✅ Adhesives and Sealants

Due to its low shrinkage and high flexibility characteristics, EOEOEA is also commonly used in UV-curable adhesives and sealants, especially for applications requiring high adhesion and dynamic performance, such as electronic component encapsulation and flexible material bonding.

Conclusion

Ethoxyethoxyethyl Acrylate (EOEOEA), with its "three-section staff"-like molecular structure featuring flexible chain segment design, low viscosity characteristics, and excellent compatibility, has become an indispensable functional monomer in many high-performance UV/EB curing systems. Whether it is used to reduce system viscosity, enhance flexibility, or optimize film-forming quality, EOEOEA provides formulators with an ideal solution.

If you are looking for a monomer that combines low viscosity, high flexibility, and excellent compatibility, EOEOEA is undoubtedly a choice worth serious consideration.

For more product details, technical data (TDS/MSDS), or sample requests, please contact us!

EOEOEA,ReactiveDiluent ,Flexibility

Previous Page

Next Page

Previous Page

Next Page

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-05-05

2025-05-05