A Complete Guide to Photopolymerization 3D Printing Technologies and Applications(Part 2)

Release time:

2025-05-08

Chapter 3: Materials for Photopolymerization-Based 3D Printing

The choice of materials is critical to the success of any 3D printing process. In photopolymerization-based 3D printing, materials primarily consist of photopolymers—liquid resins that solidify upon exposure to light. This chapter explores the different categories of photopolymers, their properties, and how they are selected for various applications.

3.1 Understanding Photopolymers

What Are Photopolymers?

Photopolymers are light-sensitive liquid resins that harden into solid structures when exposed to a specific light wavelength (UV, visible, or NIR).

They are composed of three main components:

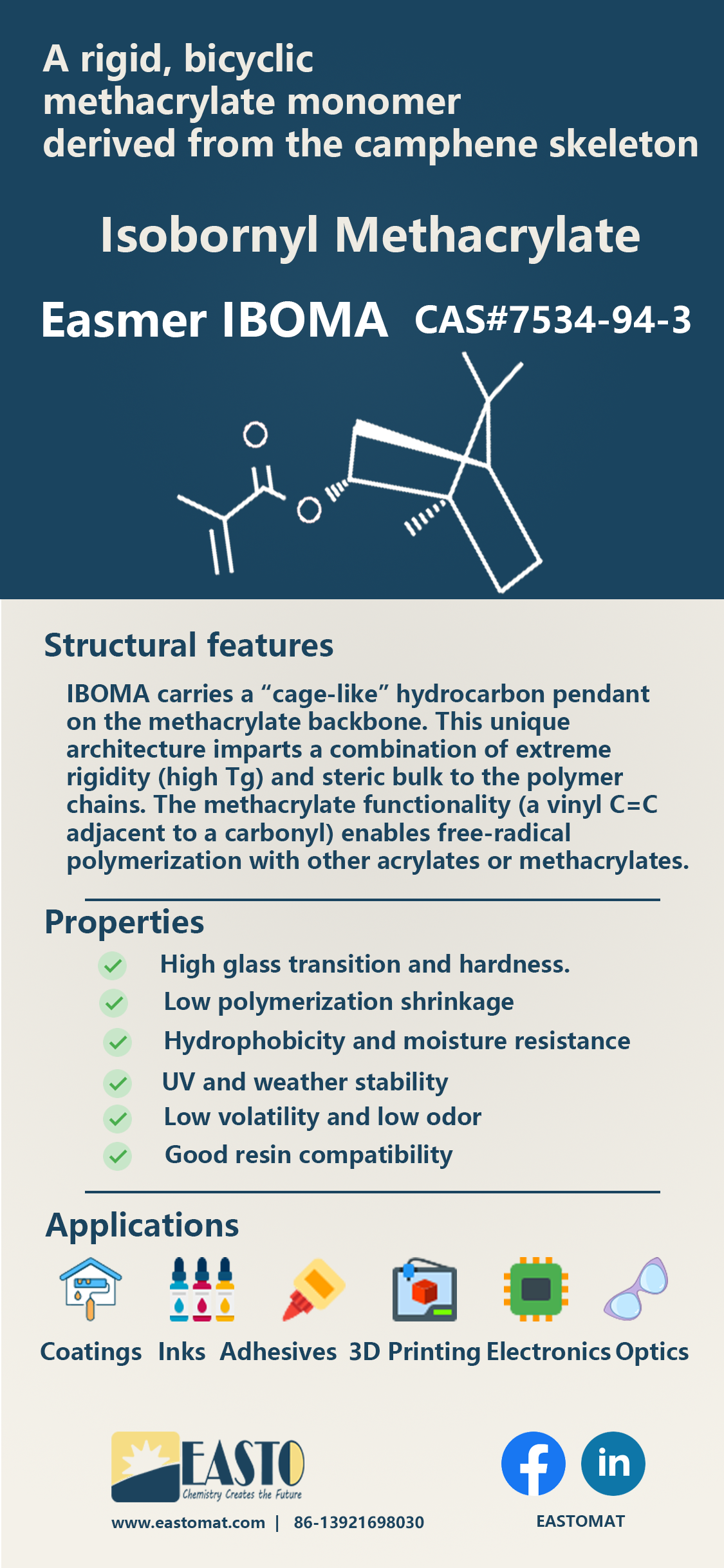

Monomers/Oligomers: The base molecules that form the polymer network.

Photoinitiators: Light-sensitive compounds that initiate polymerization.

Additives: Chemicals that enhance properties (colorants, stabilizers, tougheners).

Types of Photopolymers:

Acrylate-Based Resins: Fast curing and widely used in commercial SLA and DLP printers.

Epoxy-Based Resins: Offer improved mechanical strength and chemical resistance.

Vinyl Ether Resins: Specialized for high-performance applications.

Hybrid Resins: Combine multiple resin types to achieve balanced properties.

3.2 Key Characteristics of Photopolymers

Mechanical Properties:

Vary widely depending on the base chemistry (acrylate, epoxy, hybrid).

Can range from flexible and rubber-like to rigid and glass-like.

Important properties include tensile strength, elasticity, and impact resistance.

Optical Properties:

Transparency is a critical factor for optical applications (lenses, waveguides).

Customizable refractive index through chemical formulation.

UV resistance for outdoor applications.

Thermal Properties:

Heat resistance is essential for high-performance applications (automotive, aerospace).

Glass transition temperature (Tg) determines thermal performance.

Chemical Resistance:

Photopolymers can be engineered for resistance to solvents, acids, and bases.

Epoxy-based resins generally offer superior chemical durability.

Biocompatibility:

Essential for medical applications (tissue engineering, dental products).

Requires strict testing for cytotoxicity and biostability.

3.3 Advanced Materials for Specialized Applications

Living Photopolymers:

Use controlled radical polymerization techniques, such as RAFT (Reversible Addition-Fragmentation Chain Transfer), to enable post-curing modification.

Allow for the creation of “smart” materials that change properties under external stimuli (light, temperature, pH).

Biocompatible Resins:

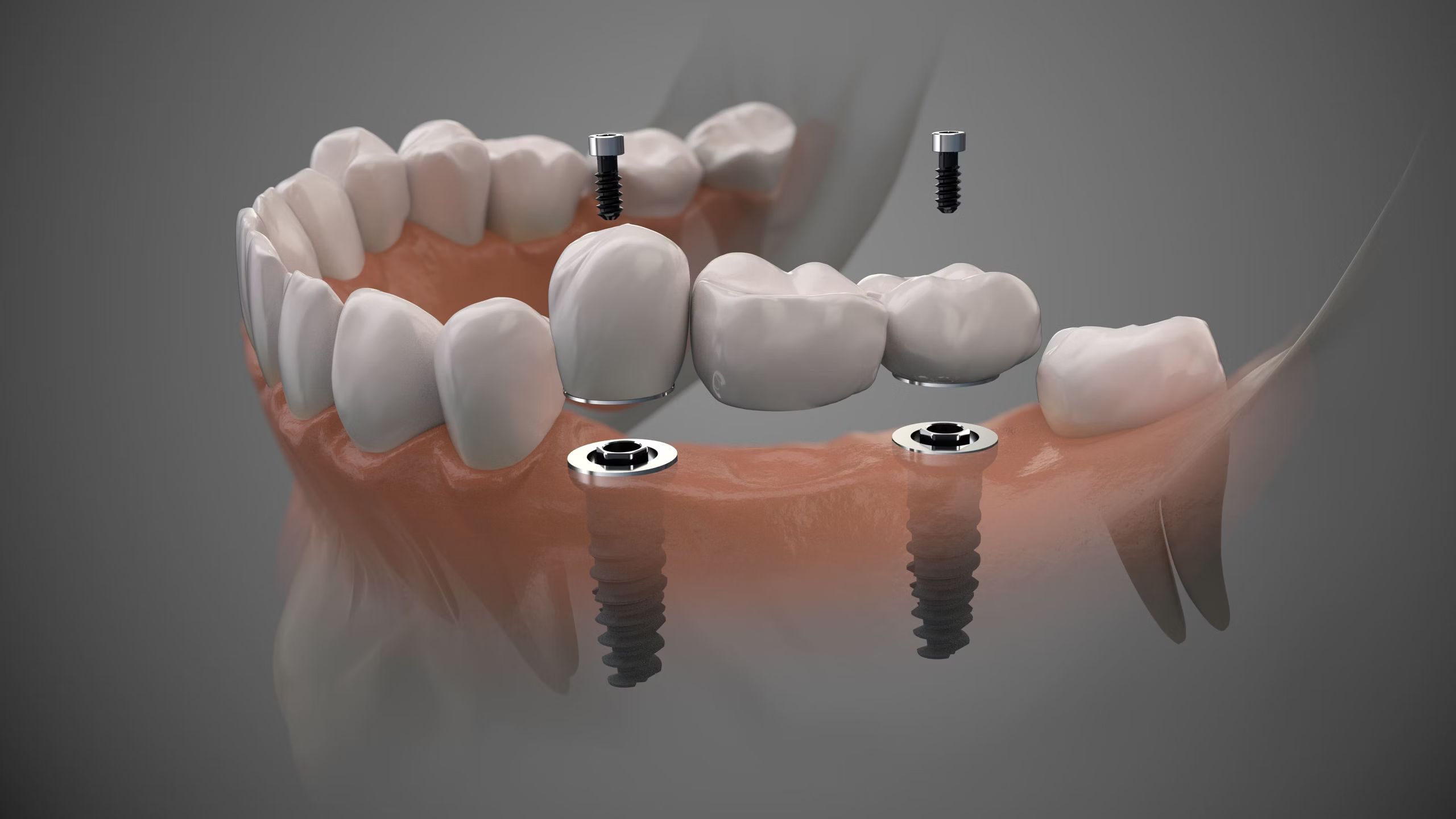

Designed for use in medical and dental applications.

Examples include hydrogels for tissue engineering, dental resins for crowns and aligners, and surgical guides.

Conductive Photopolymers:

Formulated with conductive fillers (silver, carbon) for electronics and sensor applications.

Used in printed circuits, wearable electronics, and smart devices.

Ceramic-Loaded Resins:

Contain ceramic particles for enhanced mechanical strength and heat resistance.

Widely used in dental and industrial applications.

Optical Resins:

Formulated for high transparency and custom refractive index.

Used in lenses, optical fibers, and waveguides.

3.4 Material Selection Criteria

Selecting the right photopolymer for a specific application depends on several factors:

Application Requirements:

Does the part need to be rigid, flexible, or impact-resistant?

Is transparency essential (e.g., lenses, light guides)?

Environmental Conditions:

Will the part be exposed to high temperatures or chemicals?

Is UV resistance required?

Safety and Biocompatibility:

Are the materials certified for medical use?

Are they safe for prolonged skin contact?

Printing Technology Compatibility:

Some materials are optimized for SLA, while others are better suited for DLP, CLIP, or CAL.

Viscosity and cure rate must match the printer’s capabilities.

3.5 Recent Innovations in Photopolymer Materials

Multi-Material Printing:

Printers capable of using multiple resin types in a single print.

Allows for gradient properties (e.g., flexible core with a rigid outer shell).

Adaptive Photopolymers:

Resins that change their properties in response to light or temperature.

Used in smart devices and shape-changing structures.

High-Strength Photopolymers:

Enhanced with nanoparticles (carbon nanotubes, graphene) for added strength.

Suitable for aerospace and automotive applications.

Sustainable Resins:

Biodegradable photopolymers made from plant-based materials.

Aligned with sustainability goals for reduced plastic waste.

3.6 Comparison of Major Photopolymer Types

Property | Acrylate Resins | Epoxy Resins | Hybrid Resins | Biocompatible Resins |

Cure Speed | Fast | Moderate | Customizable | Moderate |

Strength | Moderate | High | Variable | Moderate |

Flexibility | High (soft and elastic) | Low (brittle) | Variable | Moderate (tissue-compatible) |

Chemical Resistance | Low | High | Variable | Moderate |

Optical Clarity | High (transparent) | Moderate | Variable | Moderate (optical grades) |

Applications | Prototyping, consumer goods | Engineering, electronics | Custom multi-material | Medical, dental, optics |

This chapter has provided an in-depth look at the wide range of materials available for photopolymerization-based 3D printing. In the next chapter, we will focus on the critical role of photoinitiators and light sources, exploring how they drive the photopolymerization process and how they have evolved to support advanced applications.

Photopolymerization 3D Printing,additive manufacturing,DLP,SLA,3D Printing Materials

Latest News

Get a Free Consultancy

NANTONG EASTO MATERIALS TECHNOLOGY CO.,LTD.

No.118,Zhujiang Rd.,Juegang St.,Rudong County,

Nantong City,Jiangsu Province,226400,China

2025-05-14

2025-05-14